Machinery and other tools run smoothly because of the timely turning on and off of the switches. Some errors might occur due to unexpected events. In some cases, there are failures that require the immediate stoppage of the systems.

There are E-stop buttons that help manage the circuit instantly and avoid further damage. Do you want to know how you can operate these emergency stop buttons? Let’s discuss various steps and mistakes to avoid any issues.

What are Emergency Stop Buttons?

Emergency stop buttons, or E-buttons, are stop switches that cut off the electrical supply in the circuits. They help operate the circuit smoothly and manage operations in case of emergencies.

Because of these switches, it is effortless to skip any major accident. The standard features of these switches are

- Large, round, and red

- Mounted on equipment or control panels

- Designed to lock in place once pressed

- Released by twisting or pulling

How Does an Emergency Stop Switch Work?

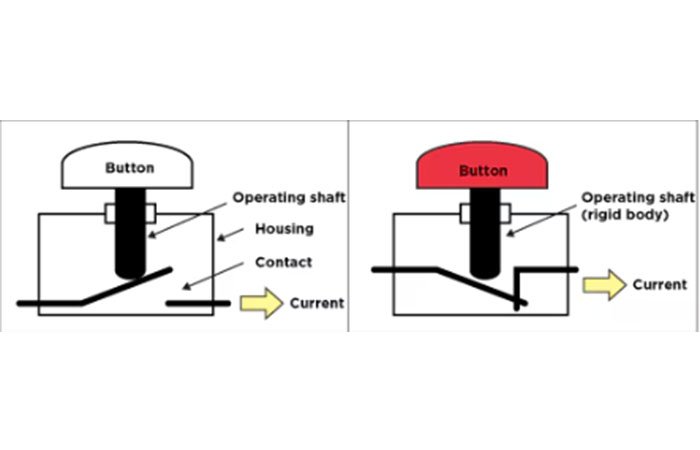

Emergency stop buttons are NC switches that have a normally closed state and let the current and power flow through the system in default state.

When failures occur, operators press the button and open the circuit cutting off the current supply. There is no current in circuit in accidents avoiding any major errors or failures that could hurt the system or operators.

Tools and Materials Needed

There are different tools and materials needed for the operations. These include:

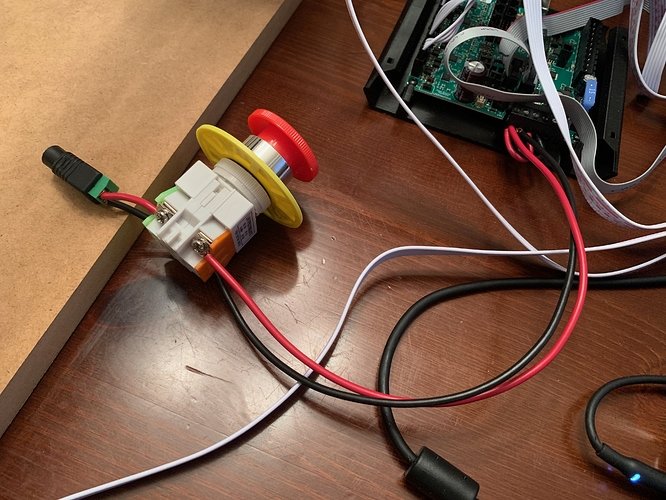

- Emergency stop button (NC contacts). They must be appropriately labeled to use them on time.

- Wires and connectors are used to secure the connection between the terminals.

- A power supply or power source provides the current flow to the circuit.

- Screwdriver and wire strippers remove the insulation and help tighten the nuts

- Relays/contactors are essential for powering heavy machinery.

- Multimeter

Step-By-Step Wiring Instructions

Are you ready to start your first DIY wiring guide? Let’s understand the whole wiring process in six steps.

Step 1: Disconnect the power

Turn off the power supply and disconnect the button from all the sources. Use a multimeter to test the voltage and current readings to understand if current is flowing. Also, gather all the tools in one place to save your day.

Step 2: Identify NC terminals on the E-stop

There can be many terminals on the E-stop; however, you have to check out the NC terminals. Common terminals include:

- NC

- 21–22

- 1–2

- Or a symbol showing a closed contact

Please don’t use the NO terminals as they are not safe to use the emergency buttons and create a safety choice. So, find out the NC terminals on the button.

Step 3: Connect the power source to the NC input terminal

Are you using the relay? If yes, connect your control power supply to the NC input terminal.

In the case of a direct power source, you can link it with the E-stop buttons. All power passes through the E-stop buttons before reaching the machinery.

Step 4: Connect the NC output to the machine’s control circuit

Since one end of the NC terminals is ready to connect. Link this end with the machinery’s control circuit, such as the motor starter coil, the relay coil, the PLC safety input, or the contactor A1 terminal.

Now the system will process power through the button. When the button is not pressed, it allows all the power from the power source to the machinery. If the button is pressed, then the power supply gets cut, and you are safe in accidental situations.

Step 5: Secure all wires and tighten screws

Using loose connections can cause extended heat-ups and might burn down your wires. Moreover, you should carefully strip off the wire insulation. Secure all cables and ensure the safety of connections.

Step 6: Restore power and test

Before you finalize, always test the system. For example, turn on the power and let the machine work. Press the E-stop button and check if the power supply is off.

Standard Wiring Mistakes to Avoid

Wrong connections or an irregular power supply can cause accidents. Here are a few tips to avoid the common mistakes.

Using NO terminals instead of NC

NO terminals means the system is off in the default state and turns on when the button is pressed. If you use the NO terminals, you are opposing the fundamental purpose of the E-stop buttons and might flare up dangerous situations.

Loose terminal screws

There are several consequences of the loose connections. For example, you press the button, but the power supply doesn’t cut off completely. Moreover, overheating and intermittent shutdowns are possible. So, tighten up all the screws effectively.

Skipping grounding

Grounding is a safety feature that lets the excessive current be grounded. Skipping grounding is pretty dangerous.

Wrong voltage rating

E-stop switches can handle a specific range of voltage. If the voltage ratings are wrong, compatibility issues occur. Match the voltage ratings of E-stop switches.

Not integrating with the main contactor or controller.

If you are in industrial settings, heavy currents and voltage can damage your devices. For that, you should never directly connect with the E-stop buttons. Instead, link the E-stop with the relay and let the power get connected to the relay or the contractor.

FAQs

1. Do I need an NC or NO contact for an E-stop?

You should use an NC switch. In the default state, this switch is on, while pressing the button in an emergency cuts off the supply.

2. Can I wire multiple emergency stops together?

Yes. You can connect and use multiple emergency stop buttons in series. Pressing one button can turn off the whole series.

3. Should an E-stop cut power directly or via a relay?

You should use a relay system to provide and cut off the power. It offers a safer mode, especially for industrial tools.

4. Does the law require an emergency stop?

Yes. In most cases, ISO 13850, OSHA, and IEC regulations require machinery to have the necessary emergency stop buttons. It avoids mishaps and provides a better protection system.

Conclusion

Emergency stop buttons are safety buttons that act in case of emergencies and turn off the whole system. In industrial settings, they offer a more crucial job for secure connections and timely management of the power supply.

You should install the emergency stop button in all cases.