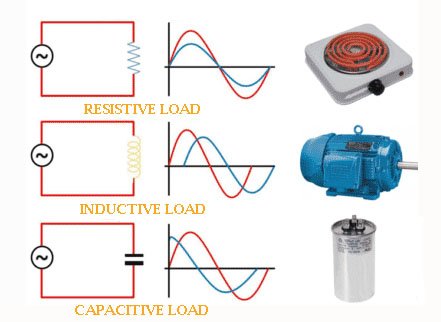

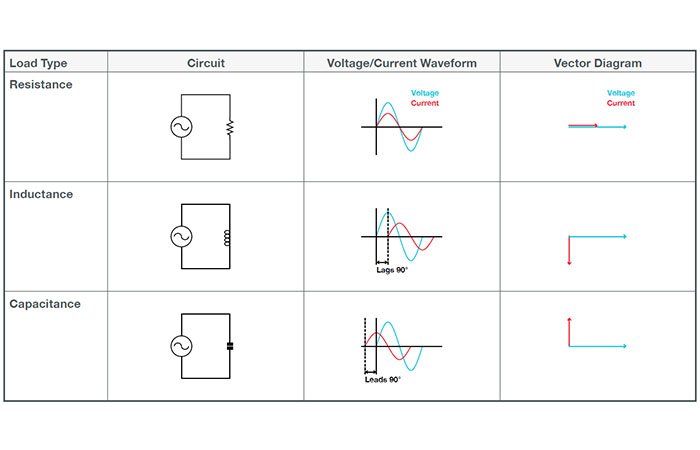

In any electrical system, you deal with different load types. Each load, inductive, capacitive, or resistive, responds differently to current and voltage. You must understand these differences to design stable and efficient circuits. This guide will take you through the practical differences between the three types.

Inductive Load

What Is Inductive Load?

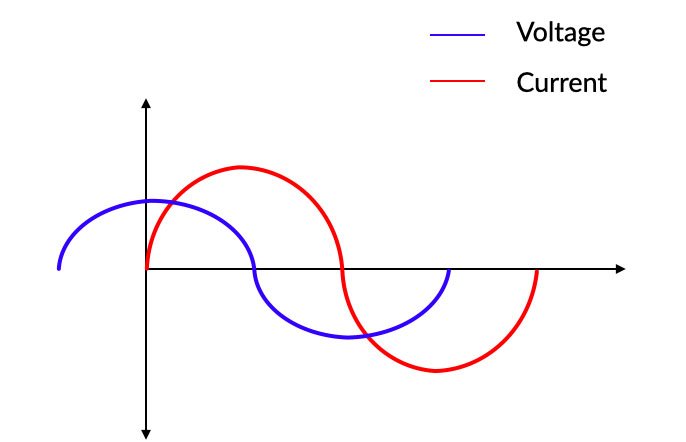

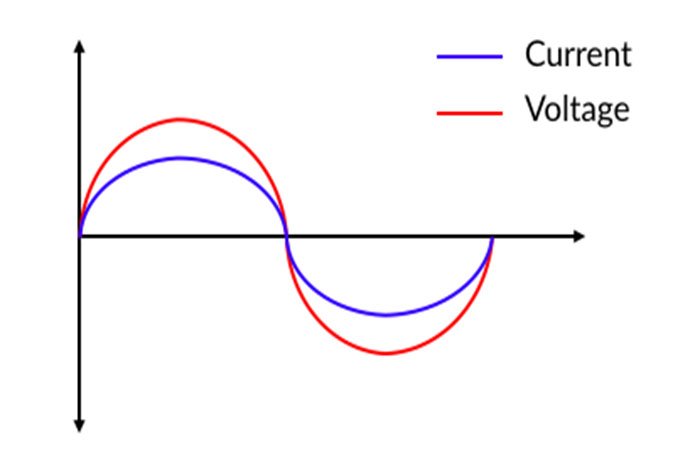

Inductive loads rely on magnetism to function. These are used in motors, solenoids, and transformers, all of which convert electrical energy into motion or force. An inductive load opposes an increase or decrease in current. They are coiled or wound. It’s done through the magnetic field generation around its coil. This implies that the current is always in lag with the voltage.

Considerations When Managing Inductive Loads.

Managing Inrush Currents and Voltage Spikes

Inrush currents can exceed normal load current many times. You should use soft starters or NTC thermistors to control this. For voltage spikes, apply snubbers or surge arresters across the load.

Power Factor Correction

Inductive loads reduce power factor by drawing reactive current. You can improve it using fixed or switched capacitors. This reduces losses and keeps your system within utility limits.

Circuit Protection and Load Switching

Inductive loads need fast, inductive-rated switching devices. Use magnetic contactors or solid-state relays with arc suppression to prevent arcing.

Industrial Applications of Inductive Loads

The following are inductive load examples:

- Electric Motors: These are used by motors in fans, pumps, and conveyors to create motion.

- Transformers: You may depend on transformers to adjust voltage levels in power distribution.

- Relays and Contactors: You use relays and contactors for switching loads automatically.

- Induction Heaters: You often use induction heating to warm metal parts without contact.

- Solenoids: You can install solenoids in valves and actuators to create linear motion.

Capacitive Load

What Is Capacitive Load?

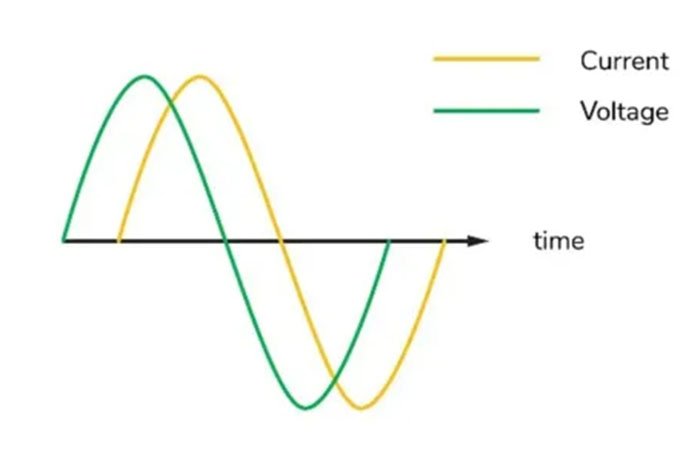

A capacitive load stores energy in an electric field. It is used in capacitor banks, long cables, or power filters. It causes current to lead voltage, opposite to inductive loads. A capacitive load draws current before voltage rises, corrects power factor, and filters signals in electrical systems.

Where are capacitive loads commonly used?

Electronic Power Supplies and Filters

You can apply capacitive loads to stabilise voltage in a short period. They react more rapidly than inductive loads in circuits. They can store and release energy as opposed to resistance loads.

Motor Start Capacitors and Correction Banks

You put in start capacitors to assist in motor acceleration. They provide current before inductive windings react. Correction banks can assist you in counteracting reactive power immediately.

Renewable and Power Grid Applications

You apply capacitive loads to stabilise the grid voltage. They react faster than inductors under sudden load shifts. Unlike resistive loads, they don’t consume energy continuously.

Challenges and Control of Capacitive Loads

Managing Overvoltage and Harmonics

You get capacitive loads to avoid spikes on the voltages. They filter the switching or power supply harmonic distortion. The presence of inductive loads aggravates harmonics concerning the rapid load change.

Risks of Resonance in AC Circuits

You should avoid resonance when using capacitive and inductive loads. When the frequencies match, the reacting voltages spike. Resistive loads will never provide resonance and must be handled with tuned filters.

Load Balancing with Mixed Load Types

You balance systems by using a mixture of these three loads. The capacitive loads compensate for lag due to inductive devices. Resistive loads stabilise current, but not phase.

Resistive Load

What Is Resistive Load?

Use resistive loads in systems that generate heat. They convert electrical energy into heat without delay. Voltage and current stay in perfect phase. No energy is stored and released over time.

Practical Examples of Resistive Loads

Heating Elements in Industrial Equipment

You employ resistive heating on the basis of constant heat output. It is a fast, responsive switching device with no lag or lead. Inductive heaters require control systems, resistive ones do not. Capacitive types are not right for direct heat transfer.

Incandescent Lighting and Electric Ovens

You can rely on resistive loads for light and heat. Incandescent bulbs convert energy to light with no delay. Ovens heat evenly without reactive current effects. Inductive and capacitive loads can’t match this simplicity.

Load Banks for Testing and Simulation

To emulate actual resistive demand, you apply load banks. They assist in testing generators, UPS, and units of power units. There is no reactive behaviour that implies correct, firm results.

Benefits of Resistive Loads

Stable Output

You get a consistent response under steady voltage input. No energy storage means zero delay or distortion. Inductive loads cause lag; capacitive ones lead. Resistive loads maintain an exact flow of current.

High Efficiency

You can convert nearly all power into useful heat. No losses appear from magnetic or electric fields. Inductive systems lose energy to field build-up. While capacitive types also waste reactive power.

Easy Setup

You install resistive loads without complex controls or tuning. No filtering or compensation devices are needed. Inductive loads need soft starts and arc protection. In contrast, capacitive setups require phase balance adjustments.

How to Use Inductive, Capacitive, and Resistive Loads

Proper Wiring

You must wire resistive loads with standard protection devices. No phase shift or reactive energy affects wiring. Inductive loads need slower fusing and arc-rated switches. Capacitive loads require surge protection and discharge paths.

Load Matching

You must size loads to match the system voltage and power. Resistive loads draw steady current. Their sizing is simple. Inductive loads need an extra margin for inrush. Capacitive loads demand reactive balance to avoid resonance.

Safety Measures

You fit thermal fuses on resistive heat equipment. Inductive loads should use arc suppression and soft starters. Capacitive loads will require discharge resistors to dissipate the charge stored. Switching behaviour should always be tested with a real load.

Inductive Loads vs Capacitive Loads vs Resistive Loads

| Factors | Inductive Load | Capacitive Load | Resistive Load |

| Energy Storage | Magnetic field | Electric field | None |

| Current–Voltage Phase | Current lag voltage | Current leads voltage | Current matches the voltage |

| Power Factor Impact | Lagging (low) | Leading (low) | Unity (1.0) |

| Start-Up Behaviour | High inrush current | Instant leading current | Stable, immediate draw |

| System Risk | Back EMF, voltage spikes | Resonance, overvoltage | Overload heating |

| Common Use | Motors, transformers | Correction banks, filters | Heaters, lamps |

Conclusion

Overall, inductive, capacitive, and resistive loads have distinct behaviours under AC power. Each load type affects power factor, switching behaviour, and protection strategy. By knowing these characteristics, you can validate proper load selection, safe wiring, and optimum system design.

FAQ’s

Q1: Can I combine different load types in one system?

Yes, you can combine these load types. You must keep a balance of reactive and resistive components to avoid instability, and or resonance.

Q2: Why do capacitive loads cause a leading power factor?

Capacitive loads release stored charge instantly. This causes current to flow before voltage builds, and leads to a power factor.

Q3: How do resistive loads behave with AC and DC?

Resistive loads perform the same under AC or DC. They draw constant current and don’t shift phase, unlike reactive loads.

Q4: Do inductive loads always need soft starters?

Not always, but soft starters are recommended for high-power inductive loads to limit inrush current and reduce mechanical stress.