Langir背光按钮开关,带来更佳体验

22mm piezo switch with plastic material with whole led , tri-color is available

Hole diameter 16mm capacitive switch with dot illumination or ring illumination

- 顶级品质与超长工作寿命

- 无数定制选择

- 简便的订购流程与快速发货

- 三种接线方式便于快速安装与即时使用

- 所有订单类型均可获得免费报价

定制您的背光按钮开关以匹配设备需求

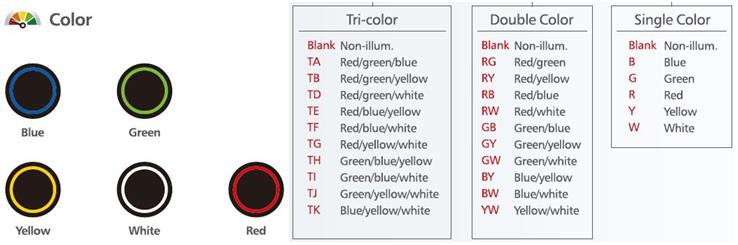

Langir背光按钮开关提供一系列明亮悦目的颜色选择,为您的应用提供丰富选项。.

可选单色包括红色、蓝色、绿色、黄色、橙色和白色。.

您还可以要求双色组合甚至三色组合,任意搭配上述颜色。.

此外,您可选择不同执行器设计,如点状、环形或激光蚀刻电源标识。.

若需要通用识别图标,可从50多种背光标签图标中选择,适用于多种控制场景,并采用背面印刷以确保耐用性。.

您还可选择特殊类型的开关,例如 压电背光按钮开关 either 电容式背光按钮开关以获得更精致外观,并在指尖享受触摸传感技术。.

Langir赋予您自由定制背光按钮开关的权利,涵盖颜色、设计、尺寸、形状、符号、配置,甚至支持自主设计。.

我们乐于听取您的创意,并将竭尽全力尽快满足您的需求。.

若您需要独特且贴合品牌的背光按钮开关,请告知我们,我们将协同合作确保您获得符合业务需求的特定开关。.

您也可以为个人用途定制背光按钮开关,无论是用于电灯开关、台灯、厨房电器、门铃,还是车辆设备。.

我们将仔细检查订单的每个细节,确保您能立即使用定制化的背光按钮开关。.

Langir将全程负责您的定制需求,并确保以最高品质交付定制背光按钮开关。.

- Factory

- Application

FAQ’s

Langir为背光按钮开关及产品目录中的其他类型开关提供365天保修。.

是的,Langir可为您提供一个或数个按钮开关样品,且完全免费。.

是的,我们将尽力满足您的紧急订单需求,并在此过程中随时向您更新进展。.

每个包装盒内大约装有40至50个带灯按钮开关,它们被精心排列在保护性泡沫中。.

而一个纸箱则大约装有500至1000个。.

然而,对于小批量订单,带灯按钮开关会采用密封塑料袋进行包装。.

好消息!您无需等待太久。事实上,您的订单一经确认便会立即发货,您将在2至3天内收到货物。.

朗吉尔带灯按钮开关——您24小时明亮的伙伴

朗吉尔带灯按钮开关是您24小时明亮的伙伴,其亮度足以在白天也清晰可见。.

我们的带灯按钮开关采用顶级材料制成,确保了坚固性和长久的使用寿命。.

作为中国领先的开关制造商,数十年来我们一直致力于提供卓越的带灯按钮开关。.

因此,当您选择从朗吉尔订购时,您完全可以确信您的制造商选择是正确的。.

多年来,朗吉尔一直向全球70多个国家供应按钮开关。.

其世界级的品质和对国际标准的遵守,证明了您——我们的客户——始终是我们最优先考虑的对象。.

除了为您提供高质量的带灯按钮开关外,我们还将帮助您为您的应用选择合适的产品。.

您的订单一经确认,所有带灯按钮开关都会经过仔细检查,以确保其最佳工作性能。.

随后它们将从工厂发出,并在几天内送达您手中。.

我们训练有素且友好的销售团队随时准备回答您的所有询问,并以快速高效的订单处理流程为您提供协助。.

朗吉尔的带灯按钮开关保证高质量,您可以在收到后立即安装使用。.

带灯按钮开关——常见问题指南

本指南将告诉您关于带灯按钮开关的基本且有趣的信息。.

您还将了解其令人惊叹的历史以及它是如何演变成今天这个样子的。.

此外,您将学习带灯按钮开关的工作原理、其重要部件、种类、多种应用,以及其他若非此全面有用的指南您可能无从知晓的知识。.

更重要的是,本指南将指导您如何找到质量最佳的带灯按钮开关。.

因此,请继续阅读本指南,以确保您只为您的应用购买最合适的产品。.

1. 什么是带灯按钮开关?

带灯按钮开关的不同类型

带灯按钮开关是一种机械开关,按下时会亮起,或者无论是否按下都一直保持亮起状态。.

它也被称为灯式按钮开关、按钮灯、带灯按钮、发光按钮、发光开关、带灯按钮、带灯按钮开关、带LED的按钮灯开关、LED灯按钮开关或带LED灯的按钮。.

与其他按钮开关类似,带灯按钮开关也有不同的种类、配置和应用。.

带灯按钮开关的外观独特,因为它能以不同颜色发光,并可以显示符号或标志,,

难怪带灯按钮开关自问世以来就广受欢迎,因为人们很容易被其多彩的灯光所吸引,其亮度即使在白天也足够显眼。.

2. 带灯按钮开关是如何制造的?

带灯按钮开关并非由单个人发明。.

它是多种发明组合于一个设备中的产物。.

您可以将其视为代表人类历史上多项发明——按钮和LED——的最佳设备范例之一。.

那么,让我们先谈谈按钮开关的历史。.

按钮开关的发明是电灯开关漫长演变历史的结果。.

您可以将其归功于英国发明家约翰·H·霍姆斯于1884年发明的速断式电灯开关。.

这项发明解决了其前身——煤气灯和弧光灯——所带来的电弧火灾隐患问题。.

速断式电灯开关开创了一种机制,无论用户以何种力度操作开关执行器,都能使触点瞬间闭合和断开。.

这一动作限制了电弧的形成,使开关寿命更长,并降低了火灾风险。.

这是其前代产品所不具备的;因此霍姆斯将其命名为“速断式”。.

即使这是一项过去的发明,直到今天您仍能在许多家庭和建筑中找到它。.

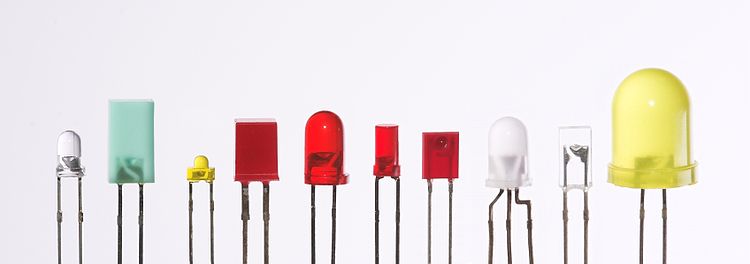

至于LED(发光二极管)的发展,这种半导体光源于1962年以红外光的形式出现,成为一种实用的电子元件。.

它是基于亨利·约瑟夫·朗德发现的电致发光现象而进行的早期发展的结果。朗德是为马可尼实验室工作的英国实验员。.

随后在1927年,俄罗斯发明家奥列格·洛谢夫发表了一份关于首次发现LED的报告。.

然而,尽管该报告在俄罗斯、德国和英国的多家科学期刊上发表,但当时它并无实际用途。.

在随后的三十多年里,LED技术经历了多次改进和发展。.

接着在1962年,詹姆斯·比亚德和加里·皮特曼在为位于德克萨斯州达拉斯的德州仪器公司工作时,开发出了半导体辐射二极管。.

这是LED的首次实际应用,在获得专利后,该公司立即开始生产红外二极管。.

第一颗黄色LED由乔治·克拉福德于1972年发明。.

他还将红色和红橙色LED的亮度提高了十倍。.

第一颗蓝紫色LED由斯坦福大学的科学与工程博士生赫布·马鲁斯卡和沃利·莱因斯于1972年创造。.

随后在四十多年后,由于名古屋大学的赤崎勇和天野浩,以及日本德岛日亚化学公司的中村修二的努力,白色LED首次问世。.

他们的发明在其他人均告失败的情况下取得了成功,白色LED彻底改变了LED灯。.

与白炽灯泡和荧光灯相比,LED灯更亮、更节能且寿命更长。.

由于全球四分之一的电力被照明消耗,且越来越多的公司寻求更好的照明效率,LED灯自此变得流行,并被应用于许多领域。.

趣闻:曾几何时,每个LED售价200美元

如今,您可以以非常优惠的价格购买LED,只需15美元就能买到1000个。.

但在1968年,可见光和红外LED(仅红色)超级昂贵,每个价格约为200美元。.

想象一下,如果它直到今天还那么贵,也许您的电视、收音机、电话和带灯按钮开关都会价值不菲。.

但感谢那些不懈改进LED发展的人们,它现在已非常实惠,并被广泛应用于众多事物中。.

发明促进了带灯按钮开关的发展

3. 带灯按钮开关是否像标准按钮开关一样工作?

直接回答是肯定的,但带灯按钮开关因其LED组件而工作方式略有不同,这是其他标准按钮开关所不具备的。.

通常,标准按钮开关的工作原理可简单解释为:

当按下按钮开关的按键时,装置内部的触点连接,允许电流通过,从而为连接的机器或设备发出开始运行的信号。.

带灯按钮开关可采用相同的工作原理,但不同之处在于它会发光。.

根据带灯按钮开关的接线方式,可以使其LED灯常亮(无论按下与否),或仅在按钮按下时点亮。.

4. 带灯按钮开关内的LED能使用多久?

与其他光源相比,按钮LED灯以使用寿命长而著称。.

因此,如果您想知道带灯按钮开关内的LED能持续多久,无需担心它会过早失效。.

LED按钮灯的使用寿命可达100,000小时,其他类型的光源相形见绌。.

白炽灯泡只能持续约1,000小时,而荧光灯最多可持续10,000小时。.

这就是为什么许多不同行业的制造商在适用时更倾向于在其产品中使用LED。.

除了LED价格实惠外,它们还具有较长的使用寿命,并为其产品增添显著价值,使其更具市场竞争力。.

全球的带灯按钮开关制造商也是如此。.

不同的LED颜色

5. 带灯按钮开关有多少种类型?

带灯按钮开关有不同类型,例如照明设计、颜色和形状各异。.

您可以找到不同的单色,如红色、黄色、蓝色、绿色和白色。.

您还可以找到双色或三色带灯按钮开关,它们结合了不同的颜色,并在按钮按下时显示颜色变化,或同时显示所有颜色。.

在形状方面,您可以找到圆形、方形、椭圆形或矩形的带灯按钮开关。.

有时您会发现形状独特的类型,这很可能是定制产品。.

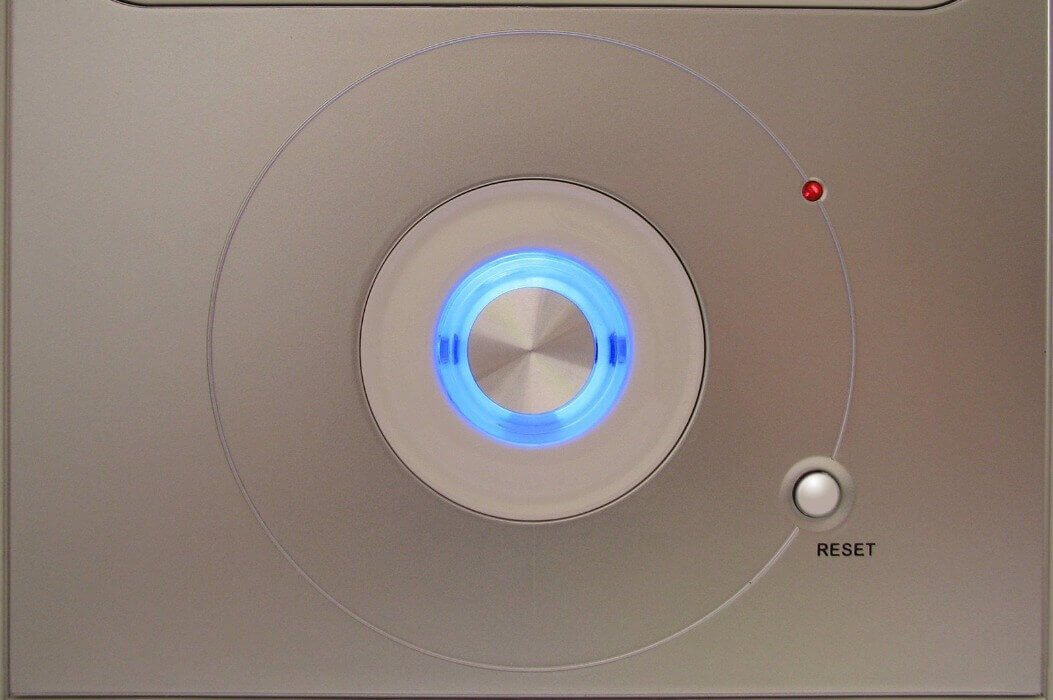

照明设计可以只是一个点,位于按钮表面的中心或靠近边缘;可以是细或粗的环形;可以是点和环形的组合;可以是带或不带环形的电源符号;也可以是显示标准符号或定制徽标的背光标签。.

例如,光环灯开关。.

不同的背光标签符号

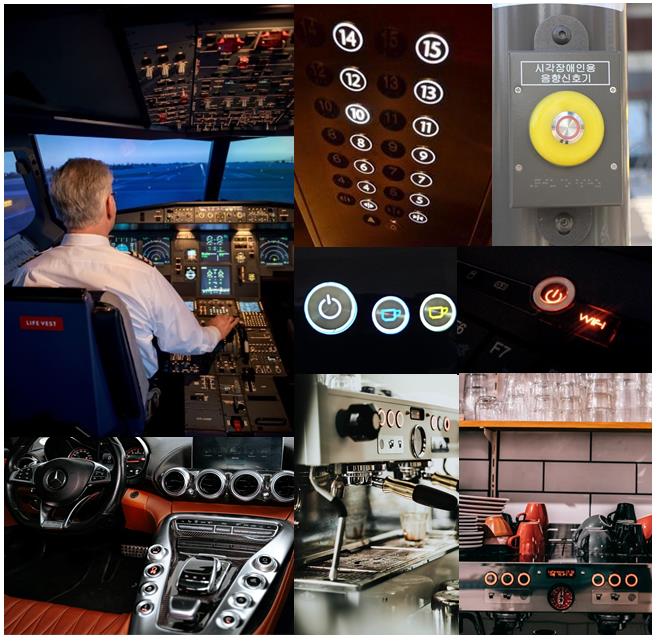

6. 带灯按钮开关适用于哪些不同类型的应用?

带灯按钮开关可应用于多种不同类型的场合,清单很长。.

除了按钮LED灯开关、门铃和电器外,以下列表也是带灯按钮开关的理想应用。.

- 农业机械

- 飞机飞行控制

- Automatic pump gas stations

- 船舶系统发动机控制

- 桥梁控制和系统

- Car wash systems

- 商业场所

- 工程车辆和机械

- 车辆仪表板

- 电气开关板

- 企业网络系统控制

- 工厂控制板

- 食品加工机械

- 医院和实验室设备

- Power utilities

- 生产控制系统

- 公共交通系统

- 空间站控制面板

- 通信系统

- 自动售货机和信息亭

可能还有更多未包含在此列表中的带灯按钮开关应用。.

带灯按钮开关的不同应用

7. 一个带灯按钮开关单元由哪些部分组成?

带灯按钮开关由多个部分组成,这些部分组合成一个单元。.

每个部分都在帮助带灯按钮开关工作并展现其最佳性能方面发挥着重要作用。.

如果您熟悉按钮开关,您可能已经对其某些部分有所了解,通常是通常可见的部分,如按钮或引脚。.

但我们列出了带灯按钮开关的不同部分,这可以帮助您找到适合您应用的开关。.

- 按钮或执行器

也称为头部,这部分是带灯按钮开关面向用户的部分。.

这是您按下以启动开关的部分,它具有不同的照明样式、颜色和设计。.

- Body

这是带灯按钮开关的外壳或机箱,内部组件受到安全保护,其他部分被固定在一起作为一个设备。.

- 也称为自锁按钮开关的端子。

引脚是连接电线的地方,通常有公共引脚、负极引脚和正极引脚。.

引脚数量可以是两个、三个、四个或更多,具体取决于开关的配置。.

它们也可以是焊片式、螺丝式,还有一些已经连接了电线(称为飞线),因此您无需再焊接电线。.

- Illumination

没有照明,带灯按钮开关就不完整。.

负责照明的部分是集成在装置内部的LED芯片。.

它根据您对引脚的接线方式发出带有颜色的光。.

- O型圈

由橡胶制成的黑色环是O形圈。.

这有助于在安装带灯按钮开关时密封头部下方与面板表面之间的间隙。.

它可以防止灰尘或任何形式的液体等外部元素进入,并在面板后部造成潮湿或积聚碎屑。.

- 这也称为螺母或安装螺母,是一种六角形金属件,用于将自锁按钮开关固定在面板或表面上。

This metal ring, typically hexagonal in shape, is responsible for securing the mounting of the illuminated pushbutton switch.

Generally, it is inserted through the grooves of the switch at the rear of the panel.

- Grooves

These are the indentation lines typically found around the switch body, through which the mounting flange is inserted.

- Spring

This metal coil enables the up or down movement of the button, storing mechanical energy when at rest.

When the button is pressed, the spring compresses and accumulates mechanical energy.

Upon releasing the pressure, the spring expands and returns to its original form.

- 触点

These are the electrical conductors positioned at specific locations inside the illuminated pushbutton switch.

There are two types of contacts: movable and stationary.

When the button of the illuminated pushbutton switch is pressed, the movable contacts establish a connection with the stationary contacts.

This connection allows electric current to flow, thereby actuating the illuminated pushbutton switch and initiating the operation of the connected machine.

- Module unit

In certain types of illuminated pushbutton switches, a specially manufactured module unit serves as the mechanical component of the standard switch.

As they lack movable parts, this helps extend the service life of the illuminated pushbutton switch.

- Touch sensor technology

Some types of illuminated pushbutton switches incorporate touch sensor technology similar to modern gadgets and devices.

This means the button can be actuated without physical force; in fact, only a light touch is required.

Some parts may not be listed here, but these are the most common components found in illuminated pushbutton switches.

Parts of the momentary push button switch

8. What are the color standards for illuminated pushbutton switches?

Although you may purchase any color of illuminated pushbutton switch to suit your preference or application, if used for business operations machinery or equipment, it is advisable to follow color standards.

According to IEC 60204-1, also known as «Safety of Machinery» (1997), using a standard color scheme helps users recognize the function of each switch.

- Red

This color signifies danger, stop, urgency, alert, or emergency.

Although this color indicates an emergency, it is mandatory to use the emergency pushbutton switch in compliance with the international standard ISO 13850 (European Standard EN 418).

It specifies that the button must have a red mushroom-head design or similar, with a yellow background.

Meanwhile, IEC 60204-1, IEC 60947-5, and NFPA 79 stipulate that the color should be bright red, as it is universally recognized for danger or emergency.

If an emergency button is used, it should not be placed near other red buttons.

- Blue

The blue color indicates that the function of the illuminated pushbutton switch is mandatory, required, involves signal change, or reset.

- Green

The green color is universally recognized as “go,” start, or power button.

- Yellow

The yellow color indicates error or caution, and sometimes signifies that the machine requires repair.

- Amber

The amber color also signifies caution, similar to yellow, but can also be used for reset, acknowledgment, maintenance, or alarms.

- Gray, White, and Black

These colors generally serve the same purposes or carry similar meanings.

They can be used for start, stop, on, off, reset, or priority functions in both non-illuminated and illuminated buttons.

They should not be used for neutral purposes or emergency buttons.

You may also refer to the guide below, which recommends push light switch button colors based on function or purpose:

- For start or on function – Use white, gray, black, or green, but not red.

- For Emergency – Use only red or the appropriate emergency pushbutton switch.

- For stop or off function – Use black, white, or gray, but not green; red may be used but must not be near an emergency button.

- For combined start/on and stop/off functions – Use black, white, or gray, but avoid red, yellow, and green.

- For a button that stops an operation when pressed and starts it when released – Use black, white, or gray, and avoid green, red, or yellow.

- For reset functions – Use blue, white, gray, or black, which may also serve for stop or off functions; black, white, and gray are ideal, but green should not be used.

- For various functions – Use black, white, or gray, but labels (text or symbols) are recommended for better identification, especially when multiple buttons are on the same control panel.

Color choices and color combinations

9. What is the voltage rating of the LED in an illuminated pushbutton switch?

The LED in an illuminated pushbutton switch has various voltage ratings, ranging from as low as 1.7 volts to as high as 220 volts.

The LED is powered by a forward voltage applied across its leads (from anode to cathode), enabling it to illuminate.

This is also referred to as positive voltage.

If the voltage flow is reversed, the LED will not emit light, which is known as reverse voltage.

As there are different LED voltage ratings, their voltage requirements also vary.

Low voltage ratings require a low voltage supply.

From another perspective, a higher LED voltage rating typically indicates a brighter illuminated pushbutton switch.

The brightness of an LED, also known as “luminous intensity,” varies by color.

- Red — 160 lumens

- Yellow — 200 lumens

- Green — 520 lumens

- Blue — 220 lumens

- White — 2000 lumens

Voltage ratings also depend on the LED color, for example:

- 1.9 Volts – Red LED, the lowest voltage rating

- 2.0 Volts – Orange and yellow LEDs

- 3.1 Volts – Green LED

- 3.4 to 3.6 Volts – White and blue LEDs

10. What is the switch action of the lighted pushbutton switch and its use?

The switch action refers to the reaction of the switch when the actuator is pressed and after the actuator is pressed.

Generally, there are two switching action types, namely momentary and latching switch actions.

For the lighted pushbutton switch, it can incorporate both types and can be:

Also referred to as a non-latching lighted pushbutton switch.

When the button is pressed, the action causes a brief change in the electrical circuit’s state.

When the button is released, the electrical circuit returns to its normal state.

This switch action is ideal for elevator call buttons, doorbells, intercoms, vehicle horn buttons, and other applications requiring a momentary switch action.

Also referred to as the maintained switch.

When the button is pressed, the action causes a sustained change in the electrical circuit’s state.

When the button is released, the electrical circuit remains unchanged until the button is pressed again, returning it to the normal state.

Typically, this type of switch action is used in kitchen appliances, emergency stop switches, flashlights, light switches, and other applications that require a latching rather than a momentary switch action.

It is critical to determine the type of switch action required for your application.

Because in most cases, one switch action cannot be used in an application where the other switch action is needed.

Choosing the wrong switch action can result in wasted time and money, business delays, dissatisfied customers, and so on.

Car horn lighted pushbutton switches

11. What is the contact position of the lighted pushbutton switch when not actuated?

The contact position refers to the state of the contacts inside the switch when the button is not pressed.

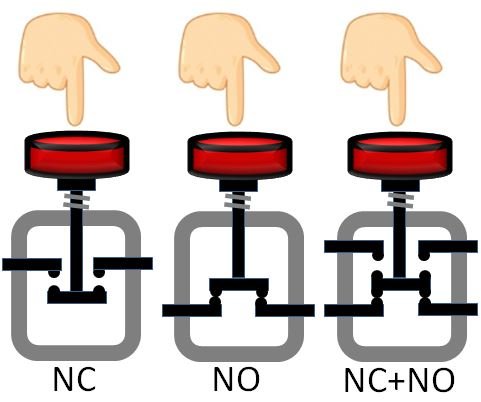

Generally, there are two commonly known contact positions for lighted pushbutton switches as well as other types of switches, which are:

When not pressed, the normally open lighted pushbutton switch has an open circuit, meaning the contacts are not connected and there is no flow of electric current.

Only when the button is pressed are the contacts connected, allowing electric current to flow and thus actuating the switch.

When not pressed, the normally closed lighted pushbutton switch has a closed circuit, with the contacts connected allowing electric current to flow, meaning the switch is actuated.

When the button is pressed, it breaks the connection of the contacts, thereby interrupting the flow of electric current.

Lighted pushbutton switch NO, NC, & NO+NC

12. What is the switching function of the lighted pushbutton switch?

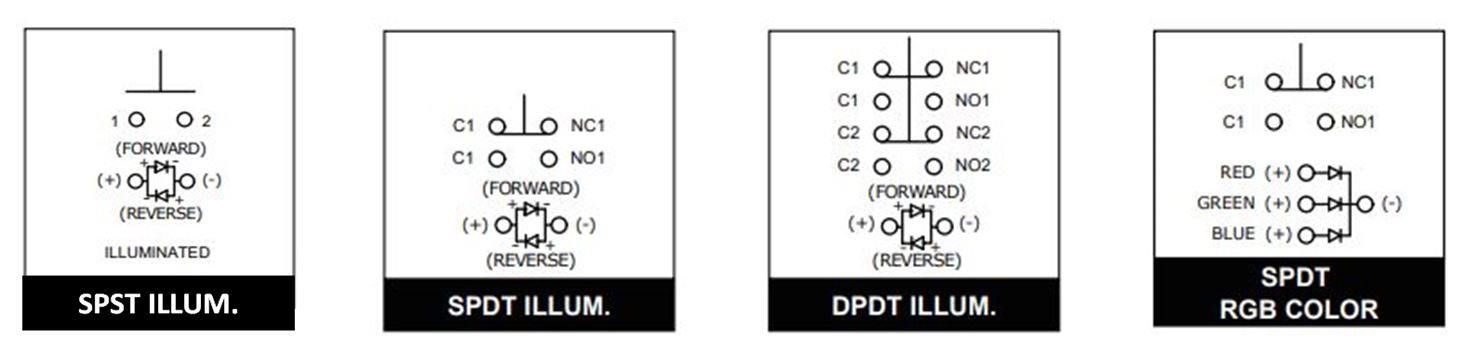

The term switching function refers to the electrical configuration of switches, including lighted pushbutton switches.

These terms can be seen on electrical diagrams such as schematic, pictorial, or wiring diagrams, along with their symbols, illustrations, and sometimes descriptions.

Advanced switching functions may be found in complex electrical diagrams, but for this list, we will focus on the most basic and common ones.

For clarity in the descriptions below, the following terms are defined:

Poles – Refers to the number of circuits the switch can control in one actuation.

Throws – Refers to the number of contact points.

Also known as Single Pole Single Throw, it is most commonly referred to as the basic switch, basic on-off switch, or sometimes a two-way switch.

It has one terminal for both input and output.

Also called Single Pole Double Throw, generally known as the changeover switch or break-before-make switch.

It can be used to control two circuits.

It has one input terminal and two output terminals.

- DPST lighted pushbutton switch

Also referred to as Double Pole Single Throw, sometimes called the double pole switch, or compared to two SPST switches in one unit.

It has two poles, meaning it has two input terminals and one output terminal.

Also known as Double Pole Double Throw, sometimes compared to two SPDT switches in one unit.

Its terminals consist of two inputs and two outputs respectively, and these terminals can be used alternately.

Different switching functions of lighted pushbutton switches

13. How is the lighted pushbutton switch different from other types of switches?

Lighted pushbutton switches differ from other switches due to the following characteristics:

- Attractive bright light

The lighted pushbutton switch is undeniably attractive due to its various illumination colors and types, which standard switches do not have.

- The illumination guides you

The lighted pushbutton switch guides you in dark places because it shines brightly, making it easy to locate.

For example, if you have a lighted pushbutton switch for your light switches, you can wire it to stay lit so that even in a dark room, you can find it and press it to turn on the lights.

Its brightness can even be strong enough to be visible during the daytime.

- Plenty of design selections

There are numerous design selections available to match any type of application.

You can always find the ideal color, design, and illumination color that best complements the color or material of the machine or equipment where the lighted pushbutton switch will be mounted.

- Multi-purpose switch

The lighted pushbutton switch is versatile and can be used in many applications.

Whether for lights, electronic devices, speakers, audio components, or appliances, you can use the lighted pushbutton switch as desired.

Alternatively, if you wish to upgrade your vehicle's plain and unremarkable controls into something visually striking and engaging, you can also replace them with illuminated pushbutton switches.

- High quality and extended service life

You can find illuminated pushbutton switches manufactured from premium materials and constructed to be robust, ensuring a long operational lifespan.

High-quality illuminated pushbutton switches can have a mechanical lifespan of up to 1 million cycles.

- Exceptional characteristics

There are illuminated pushbutton switches that feature anti-vandal and waterproof properties.

An illuminated pushbutton switch with anti-vandal properties is specifically engineered to withstand abuse and tampering.

Meanwhile, an illuminated pushbutton switch with waterproof properties can be utilized in environments near water or in damp conditions.

These exceptional characteristics are essential to consider, particularly when the illuminated pushbutton switch is intended for use in such demanding and harsh environments.

Attractive illuminated pushbutton switch

14. What materials do manufacturers use for producing illuminated pushbutton switches?

Manufacturers typically employ durable and certified materials to produce their illuminated pushbutton switches.

However, some switches are made from materials that are not long-lasting, resulting in poor quality and a short working life for the illuminated pushbutton switch.

The following is a list of materials used by manufacturers to produce high-quality illuminated pushbutton switches:

- 不锈钢

- Aluminum (e.g., natural aluminum or anodized aluminum)

- Brass (such as natural brass, gold-plated brass, or nickel-plated brass)

- Copper (e.g., nickel-plated copper or gold-plated copper)

- Silver alloy

- Chrome

- 聚碳酸酯

- Nitrile

- Silicone

- Other materials

Among these, stainless steel is ideally favored by many manufacturers due to its anti-corrosive properties and long-term durability.

其中一个例子是 Metal illuminated pushbutton switch with variants that utilize stainless steel as the material.

However, stainless steel comes in different types or grades, and these grades indicate the composition of the stainless steel, which determines its quality and characteristics.

The most commonly used stainless steel grades are:

- SAE 304

This is the most preferred stainless steel grade for manufacturing illuminated pushbutton switches.

This grade contains nickel and a certain amount of chromium, which enhance its heat and corrosion resistance.

These properties allow the illuminated pushbutton switch to perform in environments with harsh and humid conditions.

- SAE 316L

This is the second most commonly used stainless steel grade for manufacturing illuminated pushbutton switches.

This grade includes molybdenum, which enhances protection against the effects of saltwater, making it ideal for saline environments.

Stainless steel 304

15. How can you determine if an illuminated pushbutton switch is designed to be robust and durable?

To ascertain whether an illuminated pushbutton switch is robust or durable, you should look for the IK rating seal.

Not all illuminated pushbutton switches are granted this seal, as they must undergo and pass a series of tests before being rated.

These series of tests include:

- Charpy Impact test

Also known as the Charpy V-notch test.

In this series of tests, one unit of the illuminated pushbutton switch is placed in a Charpy impact machine and struck by a pendulum hammer with a specified mass and length. During the test, temperatures are varied to observe the material's reaction.

- Drop Weight test

This test comprises various methods, such as dropping the illuminated pushbutton switch from different heights or striking it with different types of hammers (e.g., free-fall hammer, spring hammer, or pendulum hammer) to assess its durability.

After these tests, the illuminated pushbutton switch is assigned an appropriate IK rating, which indicates its level of protection against impacts.

The highest rating is IK10, which is found in anti-vandal illuminated pushbutton switches designed to be tough and durable.

IK10 rating seal

16. Is the illuminated pushbutton switch protected against water ingress?

Not all illuminated pushbutton switches are designed to prevent water from entering their enclosure.

You need to look for types with high IP ratings.

A high IP rating determines whether the illuminated pushbutton switch has effective enclosure protection, not only against water ingress but also against solid ingress such as dust or dirt.

The IP rating consists of two numbers: the first number indicates protection against solid ingress, while the second number indicates protection against water ingress.

Higher numbers signify better protection against external elements.

IP67, IP68, and IP69K are the high ratings assigned to waterproof illuminated pushbutton switches,.

whereas lower IP ratings are considered water-resistant.

Waterproof illuminated pushbutton switch

17. Does the illuminated pushbutton switch have touch-sensitive button types?

Yes, you are correct. The illuminated pushbutton switch includes certain types with touch-sensitive buttons, and there are several variants.

The piezo illuminated pushbutton switch is also referred to as a piezo touch switch.

It operates on the piezoelectric principle, where mechanical energy is converted into electrical energy to complete the circuit.

A piezoelectric element is integrated into the unit; when the head is pressed, it generates an electric charge that activates the semiconductor unit, known as the Field Effect Transistor (FET).

Consequently, the FET actuates the piezo module, enabling the flow of electric current.

The FET de-energizes after dissipating the current and returns to its resistive state.

Also known as a true touch switch, the capacitive illuminated pushbutton switch is activated by a simple touch of a finger.

This is because it is equipped with touch-sensing technology that includes an electrode and a non-conductive panel.

The switch surface maintains a cycle of charge and discharge, forming a capacitance field.

This field is disrupted when anything that possesses an electric charge touches it, even if only a small amount.

That is why it reacts to the touch of a human finger, as our bodies contain small amounts of electric charge.

When the capacitance is disrupted, the switch is activated.

Other objects that naturally carry a small electric charge can also activate it.

Objects that are good conductors of electricity will have the same effect, provided you hold them while touching the head of the switch.

However, this does not occur with objects that are poor electrical conductors, also known as insulators, such as wood, stone, and fabric.

Both the piezo lighted pushbutton switch and the capacitive lighted pushbutton switch are sealed and contain no mechanical parts.

These characteristics generally make them waterproof and provide a very long service life.

Both come with integrated cables (no pins), eliminating the need for soldering or manual wire connection, thereby reducing installation time.

Capacitive lighted pushbutton switches

18. In what ways can you mount the lighted pushbutton switch?

Mounting the lighted pushbutton switch can be done in several ways.

Typically, this information is stated in the product description or included as part of the switch name.

Some types are designed for specific mounting methods, so it is necessary to know the mounting style before making a purchase decision.

The following are the different mounting styles for lighted pushbutton switches:

The panel mount lighted pushbutton switch is usually mounted on various types of panels and offers two methods: front mount and rear mount.

It is not difficult to determine whether a lighted pushbutton switch is front or rear mount, as they differ in appearance in addition to their description.

The front mount lighted pushbutton switch has a thicker head with grooves around it, and the mounting flange is fastened around the head rather than on the switch body.

In contrast, the rear mount type has grooves around the switch body—a common feature in most pushbutton switches—and the mounting flange is fastened to the switch body.

The surface mount lighted pushbutton switch is primarily mounted on a PCB, also known as a printed circuit board.

These types of pushbutton switches are usually small in size, such as the 10mm lighted pushbutton switch or the low profile lighted pushbutton switch.

The flush mount lighted pushbutton switch is typically installed flush or level with the mounting surface, providing a smooth and even appearance.

Some reminders before mounting the lighted pushbutton switch:

- Ensure you have purchased the correct mounting style for your application.

- If possible, read the mounting recommendations provided by the manufacturer.

- Ensure the diameter of the lighted pushbutton switch fits the mounting hole.

- Follow the manufacturer’s recommended panel thickness for secure mounting.

Knowing the correct mounting style for your lighted pushbutton switch helps avoid installation problems later on.

Panel mount lighted pushbutton switch

19. What if you do not want the lighted pushbutton switch to light up all the time?

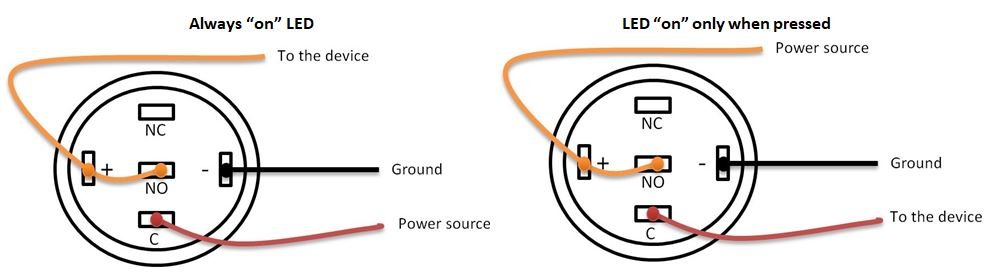

Typically, the lighted pushbutton switch can be wired in a couple of ways.

One method allows it to light up only when the button is pressed.

The other method allows it to remain lit continuously, even when the button is not pressed.

If you have purchased a 5-pin lighted pushbutton switch, it can be wired so that the LED lights up only when the button is pressed.

Here is what you do:

- Connect one wire from the positive (+) pin to the NO pin.

- Then connect another wire from the positive (+) pin to the power source.

- Connect another wire from the common (C) pin to the device.

- Finally, connect one wire from the negative (-) pin to ground.

However, if you decide to wire your lighted pushbutton switch so that the LED is always on, you can follow these steps:

- Connect one wire from the NO pin to the positive (+) pin.

- Then connect another wire from the positive (+) pin to the device.

- Use a separate wire to connect the common (C) pin to the power source.

- Finally, connect one wire from the negative (-) pin to ground.

A wiring instruction sheet is usually included in the package when you order a lighted pushbutton switch.

If not, you can visit the product listing page or the manufacturer’s website.

Alternatively, you can contact the manufacturer directly to request wiring instructions.

Wiring illustration of lighted pushbutton switch

20. Do you need a checklist before shopping for a lighted pushbutton switch?

Just as with grocery shopping, it is best to have a list of needed items, including quantities and sometimes brand names, to ensure you purchase the correct products and avoid mistakes.

The same applies when shopping for a lighted pushbutton switch, ensuring you buy the right switch for your application.

At this point, we understand that purchasing the wrong type can waste valuable time and, more importantly, lead to financial loss from the purchase cost and potential business impact due to the error.

Therefore, we have compiled a simple checklist for shopping for lighted pushbutton switches:

- What is the purpose of purchasing the lighted pushbutton switch?

- How many lighted pushbutton switches do you need? Have you included extra switches in case more are needed?

- Do you have a budget for the purchase? If so, what is the amount?

- What specific type of lighted pushbutton switch do you need?

- What switching action does your application require? (SPST, DPST, or SPDT)

- What normal contact position(s) are needed? (NO or NC)

- What type of switch action is most suitable for your application? (Momentary or latching)

- What specific color or colors do you want?

- What is the color of the switch?

- What is the color of the LED or illumination? Do you want dual or triple colors?

- Do you need an anti-vandal or waterproof (or both) type of illuminated pushbutton switch?

- What other specifications do you require for your illuminated pushbutton switch?

- The pins (solder lug, screw type, or flying leads)

- The mounting style (front mount or rear mount)

- The voltage rating

Hopefully, with this simple guide checklist or set of questions, you will purchase the correct illuminated pushbutton switch specifically needed for your application.

Having this prepared reduces the likelihood of making an error when purchasing illuminated pushbutton switches, whether for small or large orders.

This will make your shopping easier, saving valuable time and money as well.