Circuit breakers Circuit breakers are extensively utilized in electrical automation, high and low voltage electrical equipment, and are commonly observed in civil buildings. This article will provide a detailed exploration of their types, applications, functions, distinctions, and more. Whether you are a technician or a novice, reading this article will offer valuable reference insights.

What is Circuit Breaker

This is a circuit protection device used to protect circuits from problems such as overloads, short circuits, etc. When there is a problem with the circuit, it automatically cuts off the power supply to prevent further damage, protect the equipment and operators, and avoid losses. The circuit breaker will not cause damage to itself when it opens automatically, so it does not need to be replaced frequently.

Types of Circuit Breaker

Circuit breakers are essential safety devices in electrical systems. Use different circuit breakers in different scenarios. There are many types of circuit breakers with various voltages and currents. Roughly speaking, they can be divided into high-voltage circuit breakers and low-voltage circuit breakers. Generally, those exceeding 3KV are considered high-voltage circuit breakers. But how many types of circuit breakers are there that we need to know? The following are our common different types of circuit breakers:

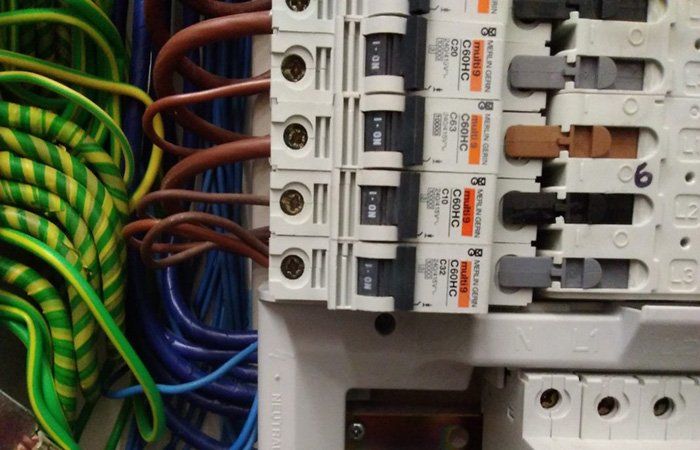

MCB

Miniature circuit breaker, mainly used for current overload and trip protection. According to voltage, there are AC and DC. Typically they have pole numbers: 1P, 2P, 3P and 4P. AC miniature circuit breakers are usually suitable for AC 50HZ/60HZ, voltage 400V, rated current below 63A, and circuit breakers used in homes, shopping malls, industries, etc. DC miniature circuit breakers are mainly suitable for DC circuits. Different poles correspond to different DC voltages. The current range is from 1A to 63A. The latest development can achieve 125A. DC miniature circuit breakers are widely used in solar systems, battery systems, and telecommunications equipment systems. The mini circuit breaker has strong breaking capacity, beautiful appearance and meets international standards.

MCCB

Also a molded case circuit breaker. As the name suggests, all accessories come in a sealed plastic box. It is an overcurrent protection circuit breaker. Generally, opened by manual operation, and its rated voltage and rated current are higher than those of min circuit breakers. Rated current from 16A to 1600A and it can withstand uninterrupted system voltage. Molded case circuit breakers are small in size and competitively priced. The application of MCCB is very extensive,they are indispensable safety devices in distribution boxes.

ACB

Also known as frame circuit breaker. All components of a frame-mounted circuit breaker are mounted within an insulating frame. A variety of accessories can be installed, and components such as contacts can also be replaced. The general rated current range is 630A ~ 6300A, which is mostly used in power distribution network systems. There are many types of overcurrent releases: electromagnetic releases, electronic releases and smart releases, as well as drawer types, mostly 3P or 4P. The air circuit breaker is large in size and has protection functions, measurement functions, auxiliary functions, special functions and communication functions.

QF

It is a high voltage circuit breaker. It has strong arc extinguishing ability, which can prevent the accident from expanding and ensure safe operation when an accident occurs. The current of the high-voltage circuit breaker is 1500A-2000A, and these arcs can be stretched to 2M, so the arc extinguishing ability is the most important function of the high-voltage circuit breaker. High-voltage circuit breakers are suitable for handling high-voltage circuits, such as substations, high-voltage power grids, etc.

GFCI

Also known as ground fault circuit interrupter , this type of circuit breaker is suitable for humid environments that are prone to electric shock. It will quickly detect unbalanced currents on the live and neutral wires and quickly cut off the power supply to prevent the risk of electric shock or electric shock accidents. Compared with MCCB, GFCI responds faster.

AFCI

Also known as Arc fault circuit breaker, this circuit breaker can detect abnormal arcs in the current and quickly cut off the power supply to prevent further expansion of the impact of the accident. This kind of circuit breaker can also add alarm function and improve the protection level of electrical fire.

In short, the types of circuit breakers are diverse. You can choose the proper circuit breaker type according to different use environments. If you want to know more information about the classification of the circuit breaker, you can search for more related articles.

Function of Circuit Breaker

Circuit breaker is an electrical device that acts as a protective umbrella for the entire circuit system. It plays an important role in protecting the entire equipment from further damage.The following are the main function of circuit breaker for your reference:

Overload Protection: When the current in the circuit exceeds the safe value of the circuit, the circuit breaker will automatically disconnect the power supply to prevent overload current from damaging the circuit and causing danger.

Current Short Circuit Protection: When an electrical fault causes a short circuit, the circuit breaker’s instantaneous function quickly cuts off power and prevents further damage, This is the basic function of circuit breaker.

Isolation: The circuit breaker can be used as a switch to isolate certain circuits without interfering with each other, making maintenance and operation more convenient.

Arc Extinguishing Function:How to isolate and extinguish long arcs between high-voltage power supplies.

In summary, circuit breakers also have long-delay, short-delay, instantaneous, and ground-fault capabilities. The diverse functions make circuit breakers highly sought after in the market.

Difference Between DC and AC Power

The choice of DC 以及 AC depends on the needs of the specific equipment or application. The difference between the two mainly exists in the flow direction and voltage level:

Flow Direction:The flow direction of DC power supply is a fixed direction, which is a stable and balanced current. As the positive and negative poles of the voltage change, the direction of the alternating current will change accordingly. Generally, AC power is used in household electricity.

Voltage Level:The voltage level of DC is constant, while the voltage of AC changes with time, so AC is suitable for long-distance transportation with little loss, while DC is not suitable for long-distance transportation.

In summary, the electromotive force, voltage and current changes of DC and AC are different, but the specific application depends on the needs of the equipment.

Difference Between AC MCB and DC MCB

Let’s analyze the main differences between DC miniature circuit breakers and AC miniature circuit breakers. Understanding these differences will help you make better choices.

Different Voltage: the rated voltage of AC small circuit breaker is 220V/380V AC, and the maximum rated voltage of DC small circuit breaker is 4P 1000V.

Different Working Frequencies: The working frequency of AC MCB is 50HZ/60HZ, while DC MCB do not have this value.

Different Arc Extinguishing Ability: DC circuit breaker is not affected by resistance and has a strong ability to disconnect the circuit, while AC circuit breaker must have a rated capacity consistent with the voltage of the connected circuit to disconnect the circuit, so it has strong arc extinguishing ability but poor ability.

Different Breaking Capacities: AC miniature circuit breakers are more likely to interrupt the circuit at zero-crossing points, thus possessing lower breaking capacity compared to DC miniature circuit breakers. In contrast, DC miniature circuit breakers can handle more demanding circuit conditions in DC systems and exhibit stronger breaking capability.

Different Applications: AC miniature circuit breakers are used to protect AC circuits and are commonly employed in residential and commercial areas. DC miniature circuit breakers are utilized in DC power supply applications, such as IT equipment and DC power supply systems.

Conclusion: Regardless of the differences and advantages between the two, the specific application should be determined based on actual circuit conditions.

Advantages of Circuit Breakers

As an electrical component, circuit breakers offer numerous advantages. The following points outline common benefits of circuit breakers:

Long Service Life: Circuit breakers can withstand multiple sudden power outages and abnormal overload conditions, resulting in a relatively long operational lifespan.

Accuracy: Circuit breakers can precisely detect abnormal currents in circuits and respond quickly to disconnect the circuit.

Fire Protection Performance: In the event of a circuit fault, timely disconnection of the circuit is essential to prevent fires.

Compact Structure: Circuit breakers feature a small form factor, with various components integrated within the housing, occupying minimal space. Miniature circuit breakers are even more compact.

High Safety: Ground fault circuit breakers, arc fault circuit breakers, etc., provide leakage or arc protection to effectively prevent accidents.

Higher Stability: With robust capabilities, compatible electrical parameters, and compliance with international standards, certified circuit breakers deliver safer performance and more stable operation.

Convenience: Simply moving the lever up or down opens or closes the circuit, eliminating the need for maintenance of the entire circuit system while energized.

In essence, circuit breakers function as the "Optimus Prime" of electrical systems and remain indispensable components across various industries.

How Do Circuit Breakers Work?

Circuit breakers consist of multiple components. Let us examine how they collaborate to enable circuit breaker ON/OFF operations.

Current Sensing Mechanisms

Thermal Trip Element: Most thermal trip elements employ a bimetallic strip composed of two metals with different thermal expansion rates. When excessive current flows, heat accumulates, causing the strip to bend due to uneven expansion. At a specific temperature (corresponding to a preset current threshold), the bending action triggers a mechanical latch, opening the circuit.

The response time is inversely proportional to the overcurrent magnitude (higher current = faster trip). This allows temporary surges (e.g., motor startups) without nuisance tripping while protecting against sustained overloads.

Magnetic Trip Coil: This is a critical component in circuit breakers, providing instantaneous protection against hazardous short-circuit currents. Its core function is to detect and respond to high-intensity short-circuit currents (typically 5–30 times the normal current). It operates within 1–50 milliseconds—faster than thermal mechanisms—and triggers instantaneously via force, independent of temperature.

Basic Structure includes an electromagnetic coil (copper winding around an iron core), a plunger/armature (movable ferromagnetic piece), a trip latch (mechanical release mechanism), and an adjustment screw (allows setting the trip threshold). Trip time varies with current magnitude (inverse-time characteristic).

The Contact System

The contact system is a crucial part of a circuit breaker, responsible for carrying current when closed and interrupting it when tripped. It ensures reliable operation under both normal and fault conditions.

The components of a Circuit Breaker Contact System include the following parts:

Fixed Contact is a stationary part attached to the breaker frame, made of high-conductivity, arc-resistant materials (e.g., silver alloy, copper-tungsten).

Moving (Arcing) Contact moves to open/close the circuit and is designed to withstand mechanical wear and arcing.

The Contact Pressure Spring ensures firm contact to minimize resistance and overheating, and prevents contact bouncing during fault interruptions.

Arc Chutes/Arc Extinguishing Chamber splits and cools the arc during interruption using deionizing plates or gas (SF6, vacuum).

In high-current breakers, main contacts carry normal current, while arcing contacts (made of harder materials) absorb initial arc damage during opening.

Generally speaking, the internal components of each type of circuit breaker vary slightly, but their working principles are similar. For more information, refer to additional articles.

Key Specifications and Ratings

Here are the critical parameters engineers must consider:

A. Rated Operational Voltage (Ue) is the maximum system voltage the breaker is designed for. Common values include 120V, 240V (single-phase); 208V, 480V (three-phase) for residential use; 600V, 690V for industrial applications; and 4.16kV, 13.8kV, 33kV for medium voltage.

B. Rated Insulation Voltage (Ui) is the voltage the insulation can withstand continuously, always higher than Ue (typically 1.25× Ue).

C. Rated Impulse Withstand Voltage (Uimp) is the lightning/surge voltage protection level, e.g., 6kV for 240V breakers.

D. Rated Current (In) is the maximum continuous current without tripping. Standard series (IEC): 6, 10, 16, 20, 25, 32, 40, 50, 63, 80, 100, 125A.

E. Ultimate Breaking Capacity (Icu) is the maximum fault current the breaker can interrupt once. Typical values:

MCBs: 6kA–25kA

MCCBs: 25kA–100kA

ACBs: Up to 200kA

F. Service Breaking Capacity (Ics) is the current the breaker can interrupt multiple times (typically 25–100% of Icu).

G. Time-Current Characteristics

| Curve | Trip Range | Typical Applications |

| B | 3–5× In | Electronics, lighting |

| C | 5–10× In | Motors, transformers |

| D | 10–20× In | High inrush loads |

| K | 8–14× In | HVAC compressors |

| Z | 2-3× In | Semiconductor Protection |

How to Use Circuit Breakers?

The use of circuit breakers involves three steps: selection, installation, and maintenance.

The first step is selecting the appropriate circuit breaker. Choose the type of circuit breaker based on the operating environment, such as miniature or ground fault circuit breakers. Determine the circuit breaker parameters according to electrical characteristic standards, including rated current and rated voltage, to establish the breaker's ratings and specifications, and then select the suitable model. Determine the number of poles based on the circuit to be protected.

Next is installation and wiring. Before installation, ensure the power is switched off for safety, and verify that the selected circuit breaker matches the current parameters. Wiring methods for circuit breakers include front-panel wiring, rear-panel wiring, plug-in type, draw-out type, rail-mounted type, etc.

Installed circuit breakers do not require frequent replacement but must undergo regular inspection and maintenance. If screws are loose, they should be tightened promptly. If the circuit breaker shows signs of aging, or if the housing is cracked or burnt, the circuit breaker must be replaced as soon as possible.

In summary, the installation and maintenance of circuit breakers must be performed in a safe environment by qualified professionals, as improper practices can lead to electrical accident risks.

Application of Circuit Breakers

Circuit breakers are used in numerous scenarios, including buildings, shopping malls, industrial settings, and national power grids. Both high-voltage and low-voltage systems require circuit breakers. The following are some common application environments:

- Industrial Manufacturing: In industrial manufacturing and production environments, circuit breakers are used to protect critical equipment from electrical faults without disrupting the production process.

- Commercial Buildings and Residences: Circuit breakers protect building circuits from short circuits or overloads, ensuring daily electricity needs are met and preventing fires and disasters.

- Solar Systems: DC circuit breakers, both small and large, disconnect fault currents and protect photovoltaic components within solar systems.

- Construction: Construction sites typically have temporary electrical systems and equipment, and circuit breakers can be used to protect these systems and devices.

Beyond these applications, circuit breakers have a wide range of uses.

FAQ

Are DC Circuit Breakers Directional?

Yes, it is directional and flows in a fixed direction.

Do Circuit Breakers Go Bad?

Yes. If a circuit frequently experiences short circuits or excessive current loads, the silver contacts of the circuit breaker can wear out, rendering it unable to carry the rated current, which may damage the circuit breaker.

Can AC MCB Use for DC?

No, the two cannot be used interchangeably.

Can I Change the Circuit Breaker by Myself?

No, you cannot. Replacing a circuit breaker is a relatively specialized task. Without understanding electrical principles, there is a high risk of electric shock. Please arrange for a professional electrician to perform the replacement.

How Do You Determine If this Circuit Breaker Needs to Be Replaced?

If there is a power outage in your home or electrical system, the first step is to check whether the circuit breaker has tripped automatically. If other circuits are functioning normally, an electrician will use a voltage tester to check whether the circuit breaker is operating correctly.