Have you ever considered what to do if a machine in your factory suddenly breaks down? At this time, the Emergency Stop button becomes crucial. Whether it's in factory equipment or elevators, it's the last line of safety. This article will take you to understand the many aspects of how emergency stop buttons work, common types and applications.

What is an Emergency Stop Button?

Emergency stop buttons, Emergency stop buttons play a crucial role in machine safety, enabling the quick shutdown of a machine in the event of an emergency. Unlike regular stop buttons, the Emergency Stop Button features a bright red and yellow color scheme with a mushroom-shaped head. This design makes them more eye-catching. Additionally, these buttons must be manually rotated or pulled to reset, preventing the machine from restarting accidentally. They are effective in preventing potential disasters.

How Does an Emergency Stop Switch Work

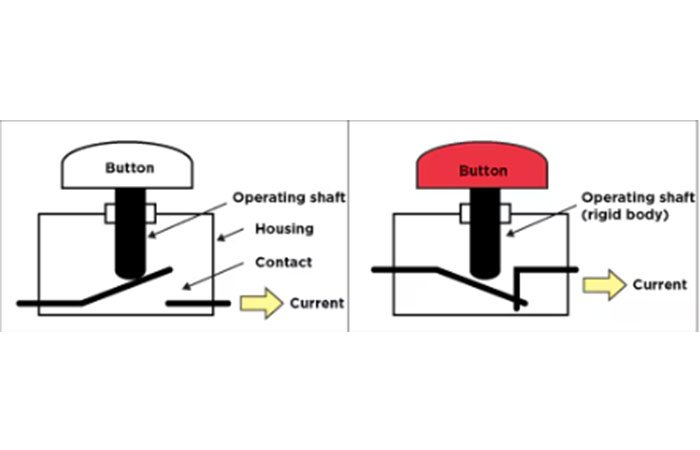

The emergency stop switch cuts off power to the machine directly through the physical circuitry. When pressed, its internal contacts cut the control circuit directly, thus disconnecting the mains power supply. Unlike regular buttons, E-stops can be triggered even during a system failure. Once activated, the button remains locked until manually reset to restart. This ensures machines stay off until the issue is fixed by workers. This simple yet critical design enables anyone to prevent a disaster from happening in under a second.

Types of Emergency Stop Buttons

Emergency stop buttons can be classified based on their application scenarios as follows:

Mushroom-head Button: This is the most common type. It is designed for one-handed use. Press lightly to stop the machines instantly.

Rope-pull Switch: Suitable for long conveyor belts. Pull the rope from any position to trigger an emergency stop.

Foot Pedal Switch: Similar to a car brake, this switch lets workers stop the machine using their feet while their hands are occupied.

Key-reset Switch: This type requires a special key to reset, which helps prevent accidental activation and enhances safety.

Where Are Emergency Stop Buttons Required?

Legal regulations require all machinery with injury risks to have emergency push stop buttons. Next, I will introduce you to some common application scenarios:

Factory assembly line: If a worker’s clothing gets caught in the conveyor belt, pressing the emergency stop switch will immediately halt the entire assembly line. This can effectively protect personal safety.

Construction sites: Emergency stops on cranes or drills prevent falling loads or machine failures that could cause collapses.

Medical equipment: When surgical equipment malfunctions unexpectedly, simply pressing the button can immediately cut off the power supply to protect patient safety.

Logistics and Warehousing: Workers can immediately stop an out-of-control forklift by pressing a button, preventing collisions and cargo damage.

Public Transportation: If the elevator catches someone or a shoe, you can find an emergency stop button near the control panel to pause the elevator.

Laboratories and chemical plants: When a leak or temperature runaway occurs, triggering the emergency stop button can immediately shut down the heating device and pump valves.

How to Install an Emergency Stop Switch

If you want to install the emergency stop button by yourself, you can follow the steps below:

Step 1: Select the Correct Location

Install the emergency stop button within an arm’s reach of the operator (approximately 24 inches). Do not place it behind machinery, in corners, or near high-temperature surfaces.

Step 2: Turn off the Power

Completely turn off the machine and lock out the power supply to prevent accidental startup while working.

Step 3: Connect the Wires

Connect the emergency stop switch directly to the machine power supply with a wire. For critical systems, it is recommended that you add a backup circuit.

Step 4: Fix the Button

Use bolts to fix the emergency stop button to the metal panel. If installed outdoors, you will need to seal the edges with a waterproof material to prevent dust and moisture from entering.

Step 5: Test and Verify

After restoring power, the machine should stop immediately when the button is pressed. It won’t restart until you manually reset it. Please ensure that you repeat the test five times to verify its accuracy each time.

Step 6: Attach the Label

Put a conspicuous “EMERGENCY STOP” sign on the top of the button. Add a simple description, like “Right Turn Reset”.

Common Mistakes to Avoid

During installation, you might face issues and feel overwhelmed. Don’t worry! Here are common mistakes and solutions to help you:

Hidden Button: It is incorrect to place the emergency stop button behind the machine or too high up. The right way to do this is to install it in a visible, easily accessible location.

Non-standard Button: Be aware that non-standard buttons may break or fail under pressure. That is why you need to purchase OSHA-compliant red mushroom head buttons.

Wrong Wiring: It is incorrect to connect the button to the computer. You should connect it directly to the main circuit.

Missing Labels: Many people will forget to label the buttons, which leads to wasting time figuring out how to restart. You should add the yellow “Reverse Reboot” label promptly after installation.

Maintenance Tips for Emergency Stop Buttons

Regular maintenance significantly extends the button’s lifespan. Here are some essential tips to keep in mind:

Monthly testing: Press and release the button each month. Ensure it stops the machine instantly and resets properly.

Regular cleaning: Use a dry cloth to wipe the button, removing any dust or grease that might cause it to jam.

Inspect wires annually: Check wires annually for frayed or loose connections. If you find any problems, replace damaged parts promptly.

Replace faded labels: Replace old or torn “stop” labels to ensure they are legible.

FAQs

1.How often should emergency stop buttons be replaced?

Replace them every five years or after they’ve been pressed 100,000 times.

2.Can emergency stop buttons work during power outages?

Yes. They can still cut power because they’re mechanical devices, even without electricity.

3.What if the button gets stuck?

Don’t try to force it! You should replace the entire unit right away.