Introduction

Electrical and electronic devices themselves pose a significant hazard. Their enclosures provide comprehensive protection to users. However, a weak and low-quality enclosure may fail under mechanical stress in adverse environmental conditions.

To withstand mechanical stresses, rating systems, such as IK, come into action and ensure protection of the devices. Do you want to know how IK rating can influence the mechanical impact and provide safety? If yes, this guide is for you. We will discuss the IK rating system and understand how this system works.

What is IK Rating

The definition of IK refers to impact protection. It is an international standard for measuring the ability of electrical and electronic enclosures to withstand external mechanical forces.

This system ranges from 1 to 10 based on the total force applied during stress conditions. Understanding and applying the IK system is reasonably necessary, similar to other standards.

Why IK Rating is Important

The IK rating is critical for various tools and equipment. It provides insight into the compatibility of the tool with required environmental conditions.

Let's review the significance of the IK rating.

Ensure Safety

With a quality enclosure that has an IK rating, you are more than safe. There is a lower chance of sparks or electrical fires. Even if a fire occurs, the enclosure contains it and keeps you safe.

Increases Durability

A robust enclosure is the first line of defense for electrical devices. If it is IK-rated, it means environmental conditions have less impact, and the tools are safer and more durable.

Better Product Compliance

Do you want to risk your life? Of course not! Thanks to the product compliance provided by the IK rating, your electrical enclosures can better withstand industrial, municipal, or international standards.

Cost Saving

The right environmental stress, proper standards, and proper safety. You can avoid extra expenses on unnecessary ratings while ensuring sufficient safety and compliance for your electrical enclosures.

How to Test IK Rating

IEC/EN 62262 has defined the specific tools required to test the IK rating of different items.

Here is how to test the IK rating.

Step 1: Gather Tools

Many impact tools are available for applying force—for example, spring hammers, pendulum hammers, or drop-weight testers.

Step 2: Apply Force

Mount the products as you typically would. Use the hammers and drop-weight testers. Apply at least five impacts in multiple directions and points to confirm uniform impact resistance.

Step 3: Check Pass

A material passes the test if there are no cracks or deformations after force application. Low-quality materials often fail and deform.

IK Rating Chart

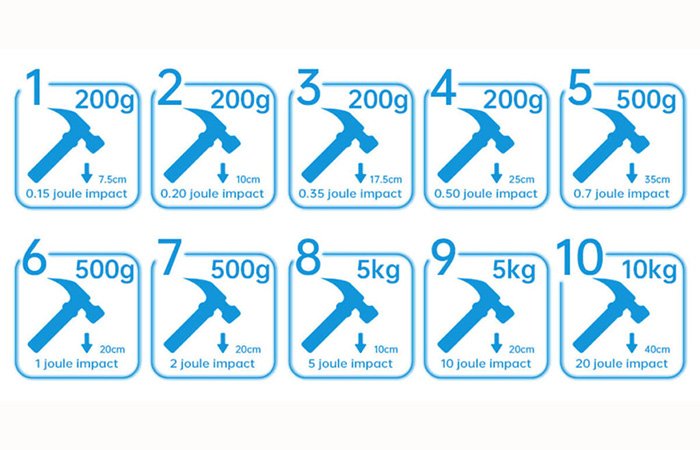

| IK Rating | Impact Energy (Joules) | Impact Example | Protection Level Description | Typical Applications |

| IK00 | 0 | No protection | No protection | Indoor use only |

| IK01 | 0.15 J | 0.2kg from 7.5 cm | Very low protection | Decorative indoor lights and fragile control panels |

| IK02 | 0.20 J | 0.2kg from 10 cm | Low protection | Office equipment and concealed light fittings |

| IK03 | 0.35 J | 0.2kg from 17.5 cm | Minor accidental knocks | 照明开关 and basic enclosures |

| IK04 | 0.50 J | 0.2kg from 25 cm | Moderate indoor protection | Residential panels and wall-mounted thermostats |

| IK05 | 0.70 J | 0.5kg from 35 cm | General indoor protection | Interior signage and school hallway lights |

| IK06 | 1.00 J | 0.5kg from 20 cm | Suitable for frequent handling | Electrical boxes and control buttons |

| IK07 | 2.00 J | 0.5kg from 20 cm | Protects against accidental tool strikes | Industrial control panels and commercial kiosks |

| IK08 | 5.00 J | 5kg from 10 cm | High resistance to hard impacts | Outdoor lighting, security housings, and parking meters |

| IK09 | 10.00 J | 5kg from 20 cm | Very high resistance; some vandal-proofing | Railway systems, factory environments, and traffic controls |

| IK10 | 20.00 J | 10kg from 40 cm | Maximum standard protection; anti-vandal | Prison fixtures, public transport, sports arenas, and ATMs |

Material and Design Impact on IK Rating

IK ratings bestow the strength and quality to the materials. Whatever material can pass this test means it has a high quality. Here are a few more aspects to see through.

Material Strength Matters

Polycarbonate or alloys have a higher durability and strength compared to cheaper plastic options. Reinforced polymer is also stronger, offering a good impact resistance compared to regular plastic. Therefore, such materials fall into the higher IK ratings.

Wall Thickness and Geometry

The higher the wall thickness, the better the impact resistance. Geometry can also contribute to higher IK ratings. For example, a round corner of a product distributes the stress and avoids unnecessary damage. Therefore, they have a higher IK rating.

Reinforcement and Ribs

Reinforcement structures stabilize the item under extreme stresses and provide flawless support. Internal ribs and cross-bracing can elevate the impact resistance.

Mounting Hardware Quality

Using premium quality mounting hardware can increase impact protection. Screws, latches, and gaskets are pretty helpful to pass the high impact rating tests. However, low-quality hardware can fail.

Protective Coatings

Protective coatings can decrease the external stress. Anti-vandal coatings or elastomer layers prevent mechanical stresses. Adding scratch resistance and UV support means better resistance.

Applications of IK Rating

Applications of IK rating vary widely because of universal usage for the impact resistance. Here are a few top applications.

Public Infrastructure

Streetlights, traffic control boxes, and ticket machines are standard public tools. Their higher impact resistance can save them in extreme environmental conditions. Therefore, they have to pass the IK rating tests to sustain in these conditions.

Industrial Environments

Industrial environmental conditions are severe for the tools. The heavy-duty tools are operating under adverse environmental conditions. Factory floors, production plants, and control cabinets should have a higher IK rating to survive better.

Outdoor Electrical Enclosures

Surveillance systems and telecom cabinets are under continuous stress and need safety from sudden burnouts. To prevent mechanical stress, electrical enclosures should have a good resistance of IK-8 or higher.

Commercial Spaces

Retail displays, parking meters, and elevator controls are under constant abuse, whether it is due to high foot traffic or environmental conditions. IK rating is also helpful in such situations.

FAQs

- How is IK rating different from IP rating?

IK rating is mainly about the impact protection and resistance against mechanical forces. At the same time, the IP rating discusses the dust and waterproofing of the devices. Both are different standards with the same goal of safety.

- Why is IK10 the highest rating?

IK10 is the highest rating because it is sufficient to test the tools against mechanical stress. Above this rating, only the military grade protection comes. Therefore, it is enough for the current tools.

- Is a higher IK rating always better?

It is not a necessity. For example, an ik04 may be fine for indoor use while an ik10 is overkill. Similarly, some high-risk areas may cost more ik10 rating compliance.

- Are IK rated products waterproof?

Not always. For waterproofing, you should check the IP rating and confirm whether your material is waterproof or not.

Conclusion

The IK rating is a vital metric in the assessment of different strengths of the tools and provides an ideal measure of mechanical resistance. Testing depends on the applications and areas where you are using the electronic devices. So, choose the rating wisely while saving your budget.