Anti-vandal switches are among the most widely applicable types of switches. This article provides detailed information about anti-vandal switches. Whether you are already familiar with them or not, reading this article will enhance your understanding. What Is An […]

What Is An Anti-Vandal Switch?

What does vandal resistance mean? Vandal resistance is a feature specifically designed to withstand certain damage or prevent accidental actuation. Switches with this feature are often designed for use in harsh environments, such as wet, salty, and corrosive conditions. Consequently, vandal-resistant switches are more rugged, durable, and safer products.

Anti-vandal switches evolved from plastic push button switches and are primarily installed on panels. With the continuous updating and iteration of technology and materials, along with user demands, anti-vandal switches have become smaller, more refined, and more widely used. Ananti-vandal push button switch features a hard metal shell, typically made of high-strength, corrosion-resistant metals such as stainless steel and aluminum alloy. This type of switch usually includes a sealing ring to isolate the intrusion of liquids and solids, providing good sealing and generally a high protection level.

How does An Anti- Vandal Switc-h Work?

Since the internal structure of anti-vandal switches varies, their operation depends on how the entire system is installed and controlled. The detailed explanation in the following section can help you understand how an anti-vandal switch works.

Robust enclosure: Indicator lights, springs, moving and static contacts, bimetallic strips, etc., are all housed within the metal enclosure, which is generally made of 304 stainless steel, 316 stainless steel, brass, aluminum, etc. The hard metal casing effectively protects the internal components. The robust enclosure also provides anti-tampering functionality, preventing external damage or prying that could alter system operation.

Sealed structure: The integral structure and sealed O-ring enable the anti-vandal switch to achieve IP65 or IP67 ratings, allowing it to operate effectively in wind and rain.

Illumination: LED lights are installed internally, which can be designed as dot illumination, ring illumination, or transparent special symbols (e.g., power symbols). Different backlit label kits can even be attached for easy replacement at any time. Bi-color or tri-color LED lights (RGB) can be selected with a common cathode or common anode according to different requirements.

Momentary or locking function: Anti-vandal switches are available in momentary 1NO, momentary or latching 1NO1NC, and momentary or latching 2NO2NC configurations. These different functions offer users a wider range of choices. When the actuator of a momentary switch is pressed, it rebounds to its initial state. When a self-latching switch is pressed, the actuator locks in that position and does not rebound.

Actuator: Actuators can be divided into flat head, high flat head, round head, and can be customized according to equipment requirements.

Key or tools: Some switches may require a key to open or close and cannot be activated without it. This also constitutes an anti-tamper switch.

In summary, you can gain a general understanding of how an anti-tamper switch works. You can also find more articles for reference or purchase some samples locally for testing.

Advantages of Anti-Vandal Switches

An anti-vandal switch is more robust because it resists damage and accidental touches. Common advantages of anti-vandal switches switches are as follows:

Anti-misoperation: This is one of the characteristics that distinguishes this type of switch from others and is also one of its most important functions. The anti-vandal switch can not only resist malicious damage but also prevent accidental touches. This feature can significantly reduce errors and ensure the normal operation of equipment.

Sturdy and durable: The anti-vandal switch features a solid shell as support, primarily using metal materials with advantages such as corrosion resistance, high-temperature resistance, rust resistance, and high strength. This ensures the switch has sufficient strength to withstand impacts from significant external forces.

Waterproof and dustproof: The metal shell is integrally formed, with no extra grooves or gaps in the button section. While protecting internal components, it prevents the entry of external solids or liquids, effectively providing water and dust resistance.

Aesthetic appearance: Different metal materials offer different visual effects. For example, the stainless steel shell exhibits several circles of metal texture, and the nickel-plated shell can reflect light. Moreover, this type of switch is compact in size and very aesthetically pleasing.

What Are Anti-Vandal Switches Used for?

The powerful functions of anti-vandal switch button push can be applied in many industries and scenarios. Common industries include:

Public transportation: Public transportation may experience different vibration frequencies due to road conditions or water surface fluctuations during operation. The stable and reliable performance of anti-vandal switches ensures that equipment functions remain unaffected and operate normally, such as buttons on control panels of buses, trains, ships, etc.

Public infrastructure: such as vending machines, public telephones, crosswalks, hot stamping machines etc. These devices are used by countless people every day and may be affected by environmental conditions or experience malfunctions due to intentional or unintentional user errors. The robust functionality of vandal-resistant switches can prevent damage caused by natural factors such as weather and environment, as well as human-induced failures.

Industrial control equipment: Industrial environments are diverse, encompassing outdoor weather and environmental influences, as well as equipment failures resulting from mechanical vibrations during production. Vandal-resistant switches can effectively guard against dust, water, and shock, prevent equipment or components from loosening, accidental contact, etc., enhance production efficiency, and ensure safety. For instance, mechanical controls, monitoring equipment, control panels, etc., can all utilize vandal-resistant switches.

安防设备: such as access control systems, monitoring equipment, etc. Although equipment in such environments is not used frequently, it is required to operate normally at all times to ensure safety and must not be subject to malicious damage or tampering. Therefore, vandal-resistant switches can ensure the proper functioning of the equipment and resist intentional destruction.

医疗设备: Medical equipment must avoid errors during use, making switches with high stability and durability, such as anti-tamper switches, essential. Additionally, medical equipment is relatively expensive; selecting vandal-resistant switches with a long service life can effectively reduce the frequency of equipment upgrades and save costs.

Types of Anti-Vandal Switches

To meet the demands of different applications, vandal-resistant switches are classified by material composition, operational mechanism, and installation method.

Material Composition: Stainless steel switches dominate outdoor and marine environments due to their corrosion resistance. Aluminum switches, on the other hand, offer lightweight options for aerospace or portable equipment.

Operational Mechanism: Momentary switches, common in emergency stop systems, briefly open or interrupt a circuit when pressed. Maintained switches, on the other hand, remain closed when pressed.

Installation Method: Panel mount designs with threaded sleeves are available for vibration-prone machines. Panel mount designs with adhesive backing allow for rapid deployment in field maintenance.

How to Choose the Right Anti-Vandal Switch

Choosing the right switch requires considering environmental, electrical, and frequency-of-use factors.

Environment: For outdoor installations, stainless steel enclosures with IP67/IP69K ratings are preferred to protect against deterioration caused by sunlight or ozone. In chemically corrosive environments, epoxy-sealed terminals should be used to guard against solvent or acid degradation.

Electrical: Switches should be rated to match the load. Low-power systems such as LED indicators are compatible with 12V DC, 1A switches. High-power motor control requires 240V AC, 10A switches.

Frequency of use: High-traffic applications such as subway controls require metal actuators with tactile feedback to withstand repeated presses. Low-use panels benefit from cost-effective plastic-coated models without sacrificing durability.

Aesthetics: Laser-etched labels can be used to enhance the aesthetics of a product and improve brand image.

How to Wire an Anti-Vandal Switch

Proper vandal-resistant switch wiring can maximize the performance and lifespan of your switch. Here are some steps for a clean and professional installation.

Step 1: Identify the Switch Terminals

Most vandal-resistant switches have:

- 2 terminals (for basic NO/NC operation)

- 4 terminals (if illuminated: 2 for switch, 2 for LED)

Check the datasheet or markings:

- NO (Normally Open) – Closes circuit when pressed.

- NC (Normally Closed) – Opens circuit when pressed.

- LED+ & LED– – For backlight power (if applicable).

Step 2: Basic Wiring (Non-Illuminated Switch)

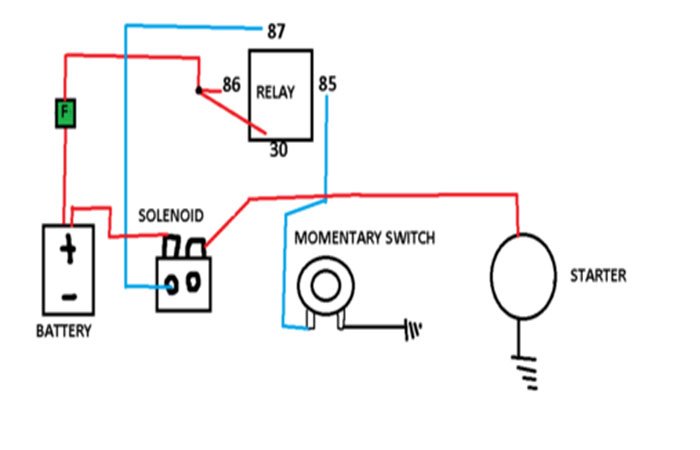

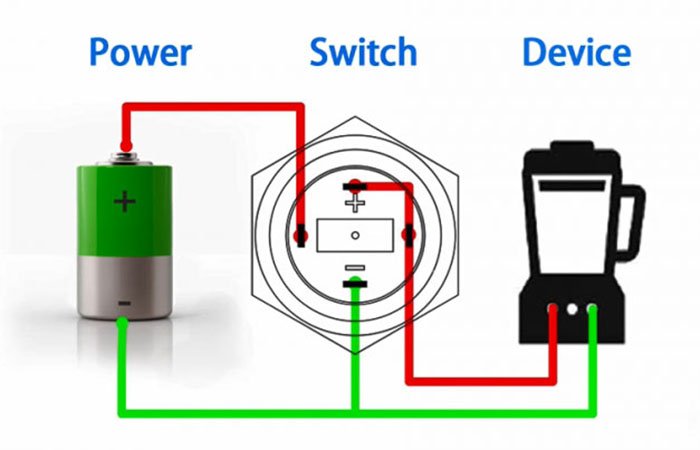

Momentary Switch (Push-to-Make)

- Connect power (+) → switch terminal 1.

- Connect switch terminal 2 → load (e.g., relay, buzzer, LED + resistor).

- Connect load → power (–) to complete the circuit.

📌 Circuit Diagram:

Latching Switch (On/Off Toggle)

Wiring is the same, but the switch stays closed until pressed again.

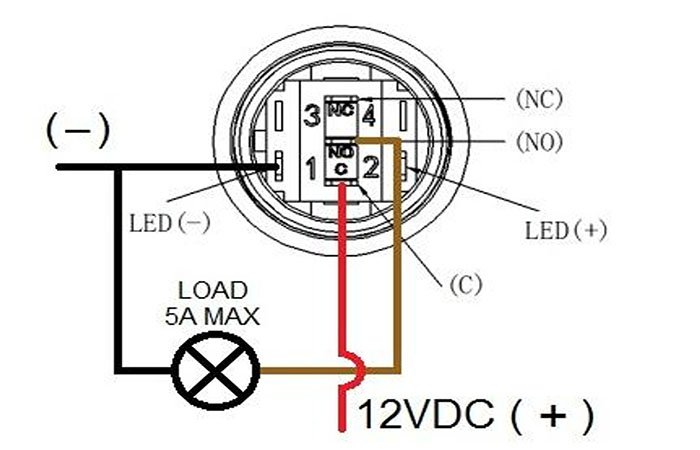

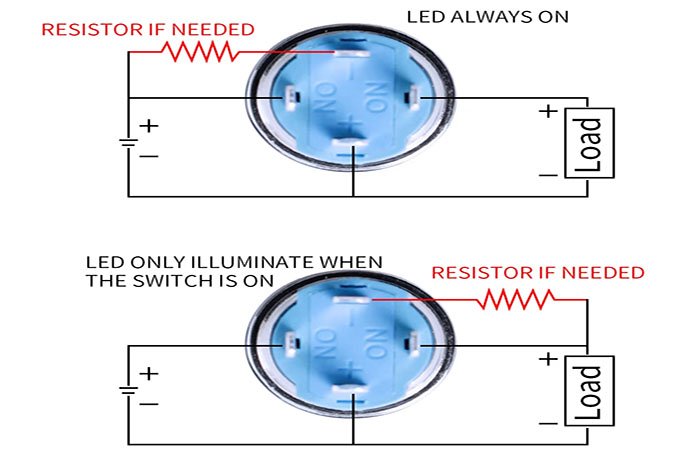

Step 3: Wiring an Illuminated Anti-Vandal Switch

If your switch has an LED backlight, it needs separate power:

- Switch Terminals – Wire as above (for the main circuit).

- LED Terminals – Connect to a power source (often same as main circuit).

- LED+ → Power (+) (add a resistor if needed).

- LED– → Power (–).

📌 Example (12V LED switch):

Step 4: Testing & Installation

- Check connections with a multimeter (continuity mode).

- Power on and test the switch operation.

- Mount the switch in a panel using the included nut.

Troubleshooting

- Switch doesn’t work? → Check polarity, loose wires, or blown fuse.

- LED not lighting? → Verify resistor value (if needed) and correct +/-.

- Intermittent operation? → Check for poor solder joints or damaged wires.

Maintenance Tips

Regular maintenance is essential to ensure the long-lasting performance of your anti-vandal switches. First, clean the switch surface regularly with a lint-free cloth and mild detergent to remove any dirt that may interfere with operation. For switches exposed to harsh environments, inspect sealing gaskets and o-rings every 3-6 months. If they show signs of wear or cracking, be sure to replace them to maintain their waterproof and dustproof properties. For electrical performance, you can use a multimeter to test resistance. This resistance should be kept low (typically below 0.1Ω) to ensure efficient current flow. By implementing these maintenance measures, you can extend the life of your vandal-resistant switches and ensure reliability.

FAQ

What sizes are available for anti-vandal switches?

Common apertures range from 10mm to 40mm, such as 12mm anti vandal switch, 16mm anti vandal switch, 22mm anti vandal switch are common sizes. Non-standard sizes can also be customized.

What is the protection level of the anti-vandal switch?

Generally, it is IP65, and can reach IP67.

What are the two-color and three-color lights of the anti-vandal switch?

Anti-vandal switches are equipped with two or three LED lights of different colors. When the button is controlled, the color of the LED light will change due to the control of different functions. The tri-color light usually refers to the RGB anti-vandal switch, which is red, green and blue.

What are the electrical characteristics of anti-vandal switches?

Anti-destruction switches are usually designed in low voltage and low current form, and can work with larger current and voltage, so as to adapt to more industries and occasions, and achieve low power consumption and high efficiency conversion. The contact resistance is generally below 50mΩ, and the electrical life is required to be at least 100,000 times.

Can I wire it by myself?

Simple low-voltage projects are suitable for DIY. For high-voltage systems or industrial machinery, call a licensed electrician to ensure compliance and safety.

Why does my switch spark when pressed?

Minor sparking is normal due to an inrush current, but large sparks suggest a short circuit or overload. Immediately disconnect the power and inspect for crossed wires or excessive load.

Can I use a 12V switch for a 240V circuit?

Never. Lower-rated switches lack the insulation and contact spacing to handle high voltages, risking fire or electric shock. Always match the switch’s rating to the circuit.