Langir Flush Mount Push Button Switches Are Your Best Choices

Anti-vandal switch, panel cutout from 10mm to 40mm; for more choices please refer to Anti-Vandal Switch pages.

Piezo switch, panel cutout from 12mm to 30mm; for more details please refer to 压电开关、 series.

Capacitive switch, panel cutout 16mm, 19mm, 22mm & 25mm. For more details please refer to 电容式开关 series.

As a leading positive flush mount push button switch manufacturer in China, Langir Electric makes this kind of pushbutton switch more perfect and elegant. Langir offers a wide range of this pushbutton switch to expand your market.

Langir Electric has obtained ISO9001 quality certification and ISO14001 environmental management system certification. Langir flush mount push button switches have passed numerous certifications and test reports such as CE, RoHS, REACH, IP65, IP67, IP68, IP69K, IK10, etc.

Customize Your Flush Mount Push Button Switch

Langir flush mount push button switch is an excellent option for maintaining an elegant and clean appearance in your area.

In addition to its various applications, Langir flush mount push button switch is highly certified and tested. All these features are available across the entire series of anti-vandal push button switches, piezo button switches, and touch-sensitive switches..

If you are considering acquiring this flush mount push button switch and customizing it, we can prepare it for you. Our broad selection of flush mount push button switches is also customizable.

From the width and depth of the head to the length of the switch, you can customize it to fit your needs. You can also specify the length of the flush mount push button switch you require.

We ensure that our series of flush mount push button switches do not protrude excessively from the surface. This makes our flush mount push button switches safe and space-saving.

You can choose your flush mount push button switch from materials such as stainless steel, brass-plated nickel, or anodized aluminum, among others. In fact, some of our previous clients have opted for flush mount push button switches made of high-quality metal materials.

Our experts will assist you with the specific details if you are unsure about the features of the flush mount push button switch you need. Discuss your requirements with us, and we will develop an actual product for you.

- Factory

- Application

- E-Catalogue

FAQ’s

They provide security and reliability in industrial machinery and building equipment.

All series of anti-vandal switches, piezo switches, and capacitive switches have this feature.

Yes, Langir flush mount push button switch is very popular worldwide.

Certainly, it would be our pleasure to do that for you.

目前我们常采用不锈钢、镀镍黄铜、阳极氧化铝等材料制造。.

Langir push button switches come with a 365-day warranty.

Langir Flush Mount Push Button Switch

Langir Electric is your reliable and professional supplier for flush mount push button switches.

Langir offers a complete line of this kind of switch with bushings from 8mm to 30mm. You may also want to know additional measurements, such as the width of the head, the depth of the head, and the length of the switch, so you can drill a hole to achieve a flush fit. Langir provides complete switch drawings for your reference.

The head of Langir flush mount push button switch protrudes with a thickness of 2mm; the flat surface and edges are very streamlined, made of lathed stainless steel 304. However, for piezo switches and capacitive switches, the head is up to 4.5mm higher than anti-vandal switches. Please take note of this point.

Langir flush mount push button is safe and space-saving; the contact block protrudes from 12mm to 41mm behind the panel. The silver contacts inside and the mechanical latching function ensure the switches are safe when pressed.

Langir flush mount push button switches are perfect for various applications. One of our Latvia customers required customization of our Anti-Vandal Switch L22M series. We redesigned the drawing according to their description, and it eventually became our new series: L22O rear mounting series..

Due to this metal material, Langir flush mount push button switches are very elegant in shape and easy to clean. As long as you have an idea, we can customize it to any possibility.

With 24/7 support, your inquiry will receive our promptest reply. Contact us now!

Flush Mount Push Button Switch — FAQ Guide

In this FAQ guide, you will learn countless interesting things about flush mount push button switches.

From its different kinds, sizes, shapes, colors, and the wide range of applications it is used for.

You will also learn some truly helpful information about flush mount push button switches that will assist you in your purchasing decisions.

After reading this FAQ guide, you will find that you can better select the most suitable flush mount push button switch with the knowledge this guide has provided.

So, before you place your order, read this guide to ensure you are purchasing only the highest quality flush mount push button switch available.

1. What is a flush mount push button switch?

Flush mount push button switch

By definition, a flush mount push button switch is an electromechanical switch mounted with only the face or actuator exposed, surrounded by a case or box that is a separate part from the switch.

The flush mount push button switch is sometimes called a panel mount due to similarities in the mounting method used.

It is also referred to as a flush push button switch, push button flush mount switch, flush mount switch, or flush mounted switch.

Like other types of push button switches, the flush mount push button switch also comes in an extensive assortment of different types, colors, shapes, and other variations.

2. How does the mechanism of the flush mount push button switch work?

The inner workings of the flush mount push button switch are generally the same.

To activate the flush mount push button switch, you press the button or actuator where the movable contacts are attached.

The push action allows the movable contacts to make contact with the static contacts on the terminals and the electromagnet adsorption device to initiate the current flow, therefore, activating the function of the flush mount push button switch.

While other types of the flush mount push button switch work a bit differently because of their different internal parts.

For example, the piezo flush mount push button switch would have a piezo assembly module unit inside its switch and the actuator is touch activated.

3. What comprises the structure of the flush mount push button switch?

The flush mount push button switch is generally composed of several parts that make up its structure.

Typically, the flush mount push button switch comprises of the following parts:

- The head or the actuator – This is the button that you press when you want to activate the flush mount push button switch.

- Shell or casing – Also known as the enclosure of the flush mount push button switch.

- Pins – Also called the flush mount push button switch terminals where the wires or switch plug-in socket is connected.

- Mounting flange – This is the hex shaped nut that is used to fasten the flush mount push button switch from the back

- Rubber ring – This is the O-ring or the rubber sealant that is positioned under the head or the actuator before mounting the flush mount push button switch so that water or dust cannot enter and cause damage at the back of the switch.

The flush mount push button switch’s internal parts are comprised of the contacts, spring, and LED chip for the illuminated types.

And there are other types of flush mount push button switches that don’t have movable parts such as the piezo switch.

Parts of the push button switch

4. What are the different flush mount push button switch types and forms?

There many different types and forms of the flush mount push button switch.

You can always find one that is perfect for your application use.

The list below is some of the flush mount push button switches kinds that you can find available in the market:

- Metal flush mount push button switch

- Momentary flush mount push button switch

- Latching flush mount push button switch

- Anti vandal switch flush mounted

- LED flush mount push button switch

- Piezo switch flush mounted

- Capacitive switch flush mounted

- Low profile flush mount push button switch

- Recessed push button switch

Capacitive switches

5. What are the common properties of the flush mount push button switch?

Since there are many types and forms of the flush mount push button switch, there are also different properties that describe them.

These properties are very important when it comes to finding the right flush mount push button switch because these are some of the basic information that you look for.

| Diameters | Actuators | 内部机制 | Colors |

| 10毫米 | 平头 | Solder lug | 黑色 |

| 12毫米 | Raised. | Screw type | Green |

| 16毫米 | 方头 | Wire leads | White |

| 19毫米 | Ring symbol | Feed-through style | Orange |

| 22毫米 | Power symbol | Quick connector blade | Amber |

| 25毫米 | Ring and power symbol | Chrome | |

| 30毫米 | Laser etched head | Red | |

| 带照明 | Yellow | ||

| Non-illuminated | Blue | ||

| Recessed push button | 灰色 | ||

| Ivory | |||

| Gold |

Illuminated push button switch application

6. What is the difference between panel mount, surface mount, and flush mount push button switch?

| 面板安装 | 表面安装 | 齐平安装 | |

| Switch structure | The panel mount push button switch has a regular push button switch appearance but other kinds have thicker-looking actuators with grooves around its sides for the front panel mounting style. | The surface mount push button switch would typically have the same appearance as regular push button switches but would sometimes have a low profile. | The flush mount push button switch would have a similar appearance to the regular push button switches but would generally have a flat head actuator style. |

| Mounting style | The panel mounting style has two types which are the front and rear panel mounting styles. The panel mount push button switch is generally installed on panel material. | The surface mount push button switch is usually mounted on a surface area or PCB. | The flush mount push button switch mounting style follows a hole-fitted mounting method to provide better surface clearance. |

Push button switches on a panel

7. What are the operating types of the flush mount push button switch?

The flush mount push button switch has two major operating types and each type produces a specific action.

The two major operating types of the flush mount push button switch are the following:

- 齐平安装自锁按钮开关

- In this type, when you press the button or the actuator of the flush mount latching push button switch, it remains in its depressed state unless you press the button again, thereby allowing it to spring back into its normal state.

- Also referred to as a flush mount push button latch.

- Examples include push button light switches, television power buttons, game console power buttons, etc.

- Flush mount momentary push button switch

- In this type, you must hold down the button to actuate it; releasing the button causes it to return to its normal state.

- Also known as the flush momentary switch or flush mount momentary switch.,

- Some examples are doorbells, car horn buttons, car power window controls, automatic blind control buttons, and so on.

These operating types are critical when selecting the appropriate flush mount push button switch, as choosing the wrong type would render it incompatible with the intended application.

Elevator push buttons – momentary applications

8. What are the default contact positions of the flush mount push button switch?

The default contact positions of the flush mount push button switch describe the internal state of the contacts when at rest or not actuated.

The operating types of the flush mount push button switch also have two kinds of default contact positions, namely:

- Normally open flush mount push button switch

- The contacts are normally open until the actuator is pressed, which moves them to connect and allow current to flow.

- This is also known as the push-to-make flush mount push button switch.

- Normally closed flush mount push button switch

- The contacts are normally connected, allowing current to flow, and the connection is broken when the actuator is pressed.

- This is also called the push-to-break flush mount push button switch.

Normally open push button switches

9. What are the electrical control circuit classifications of the flush mount push button switch?

The electrical control circuit classifications of the flush mount push button switch are also known as contact forms.

This defines the number of poles and throws of the flush mount push button switch.

The term “pole” refers to the number of circuits that the flush mount push button switch can control within one unit.

The term “throw” refers to the number of positions of the actuator.

There are four standard electrical control circuit classifications for flush mount push button switches, which are:

SPST | SPDT | DPST | DPDT |

| SPST – Stands for Single Pole Single Throw, commonly known as a basic on/off switch or two-way switch. | SPDT – Stands for Single Pole Double Throw, also referred to as an A/B switch. | DPST – Stands for Double Pole Single Throw, capable of controlling two circuits. | DPDT – Stands for Double Pole Double Throw, defined as two SPST switches combined. |

| These types of switches can connect and disconnect two terminals and have only one “on” position. For example, the SPST push button switch, or the flush mount on/off switch. | These types of switches have two “on” positions and only one input terminal. For example, SPDT push button switch. | These types of switches have two «on» positions and also have two input terminals. | These types of switches can use either of the two terminals and can be wired to function as an SPST. For example, DPDT push button switch. |

10. What is a flush mount push button switch made from?

If you have been examining flush mount push button switches, you will notice that they are most often made from stainless steel.

However, some other types and models use different materials such as aluminum, silver, brass, copper, silicon, ceramic, polycarbonate, and so on.

But the most prevalent material is stainless steel, and not just any kind of stainless steel.

Stainless steel comes in various types and compositions that enhance its features and provide better protection for its intended applications.

Sometimes it is alloyed with certain amounts of chromium, titanium, molybdenum, aluminum, carbon, silicon, nickel, and other elements to improve durability, corrosion resistance, and high-temperature resistance.

Two well-known types of stainless steel are used for making flush mount push button switches, classified by grade.

These are stainless steel grades 304 and 316, which incorporate different elements to enhance their quality.

- SAE 304 stainless steel

- This is the most commonly used stainless steel, containing 18% to 20% chromium and 8% to 10.5% nickel.

- It is also known as 18/8 stainless steel, commonly used for cookware manufacturing, and referred to as A2 stainless steel outside the US.

- It offers better corrosion and heat resistance than regular steel and is easy to fabricate.

- Besides manufacturing flush mount push button switches, it is also used to produce equipment and appliances for the food industry, as well as in other sectors such as automotive and architectural construction.

- SAE 316L stainless steel

- The second most commonly used stainless steel grade, primarily composed of iron, 16% to 20% chromium, 10% to 12% nickel, and 2% to 3% molybdenum, plus less than 1% sulfur, silicon, and phosphorus.

- It has superior corrosion resistance due to the added molybdenum, which helps resist the corrosive effects of salt in seawater.

- It is widely used in the food processing industry, medical and pharmaceutical equipment, wastewater treatment in marine applications, etc.

316L stainless steel for push button switches

11. What are the primary industries that use the flush mount push button switch?

Flush mount push button switches are used in a wide range of applications across various industries, such as:

- Food and beverage

- Food service equipment

- Automotive

- Construction vehicles

- Aggregate

- Asphalt paving

- Packaging

- Industrial equipment

- Metal stamping

- Metal forming

- 航空服务

- Power utilities

- 印刷机械

- 纸浆和造纸

- 物料搬运

- 化工厂

- Petrochemical

此外,嵌入式按钮开关还有许多其他应用,例如家用电器、电灯开关、门铃、大门及车库门控制开关等。.

嵌入式按钮开关的应用

12. 什么是延时嵌入式按钮开关?

延时嵌入式按钮开关专为定时控制特定功能(如照明、通风和供暖)而设计。.

当按下嵌入式按钮开关时,可设置功能执行的持续时间,时间结束后将自动关闭。.

时间设置通过设备背面的拇指轮完成。.

例如,当按下用于照明目的的延时嵌入式按钮开关时,照明将仅持续设定的时间。.

延时嵌入式按钮开关提供多种可精确设置的时间范围。.

延时按钮开关

13. 嵌入式按钮开关的安装尺寸是多少?

嵌入式按钮开关的安装尺寸取决于以下几个因素:

- 嵌入式按钮开关的尺寸

- 面板后方(有时为面板前方,适用于带防护的开关站)的间隙

- 安装嵌入式按钮开关的面板、板材或背板的厚度.

例如,16毫米嵌入式按钮开关需要16毫米的安装孔、0.059英寸的表面间隙、不带导线时0.886英寸的后方间隙,以及10毫米的面板厚度。.

14. 嵌入式按钮开关适用的面板厚度是多少?

大多数制造商会为其每款嵌入式按钮开关产品向客户提供推荐的面板厚度。.

一般而言,适用的面板厚度应在10毫米至12毫米之间,且制造商通常要求表面平整。.

提供此测量标准是为了避免以下问题:

- 面板过薄可能无法稳定支撑嵌入式按钮开关的安装和操作。.

- 面板过厚可能无法牢固固定嵌入式按钮开关,导致安装不稳定。.

- 若面板表面不平整,嵌入式按钮开关可能无法密封安装,导致灰尘和水进入面板后方区域。.

15. 如果嵌入式按钮开关的安装孔切割过大,应如何处理?

有时可能会出现切割的孔洞略大于所购嵌入式按钮开关实际直径的情况。.

无需担心,因为通常允许约0.3毫米的测量误差。.

但如果不幸切割的孔洞超出此范围,可使用另一块额外的面板板材,或更好的是购买一块标识板来弥补多余空间,同时获得更美观的外观。.

按钮开关标识板

16. 是否有LED类型的嵌入式按钮开关?

是的,有多种LED类型可供选择,具有不同颜色和符号。.

最常见的是电源符号和环形符号,以及两种设计的组合。.

除此之外,还有背光LED类型,提供多种背光标签可供选择。.

还可根据您的理想设计规格定制图标标签。.

选择背光LED类型具有以下优点:

- 采用防刮擦聚碳酸酯材料制成

- 背面印刷,经久耐用

- 防水粘合剂

- Customization options

17. LED嵌入式按钮开关的制造质量要求是否很高?

由于LED嵌入式按钮开关应用广泛且多样,其生产要求较高。.

但这并不意味着消费者可以随意从任何制造商处购买LED嵌入式按钮开关。.

这不仅适用于LED类型的按钮开关,也适用于其他类型。.

因此,始终寻找可信赖的制造商以避免后续问题至关重要。.

LED嵌入式按钮开关

18. 是否有蜂鸣器类型的嵌入式按钮开关?

是的,目前市场上有多种蜂鸣器类型,例如:

- 闪烁蜂鸣器类型

- 交替闪烁颜色类型

- 蜂鸣器关闭时LED关闭

- LED常亮蜂鸣器类型

- 双色LED闪光蜂鸣器类型

- 环形照明蜂鸣器类型

其他可用的定制类型和功能请咨询制造商。.

蜂鸣器类型嵌入式按钮开关

19. 如何拆卸嵌入式按钮开关?

嵌入式按钮开关安装简便,拆卸也同样容易。.

拆卸嵌入式按钮开关时,可遵循以下简单步骤:

- 首先,必须能够接触到面板背面,因为大多数拆卸步骤需从背面进行。.

- 移除接线连接或开关插座插头。.

- 松开安装法兰,直至其完全从嵌入式按钮开关上取下。.

- 然后,在面板正面使用按钮拆卸工具,小心地撬起并拉出嵌入式按钮开关,直至其完全取出。.

- 如果没有按钮拆卸工具,可以使用任何能够从面板上撬起嵌入式按钮开关头部的薄型材料。.

- 检查面板后方可能遗留的任何线缆。.

六角螺母和O型圈

20. 嵌入式按钮开关的产品寿命有多长?

嵌入式按钮开关的产品寿命可持续多年,具体取决于其质量。.

产品寿命这一术语也可称为使用寿命、工作寿命等。.

嵌入式按钮开关有两种产品寿命,分别称为机械寿命周期和电气寿命周期。.

机械寿命周期指嵌入式按钮开关机械部件的寿命,而电气寿命周期涉及其电气部件的寿命周期。.

平均而言,高质量的嵌入式按钮开关机械寿命周期约为1,000,000次,电气寿命周期约为200,000次。.

21. 哪些因素影响嵌入式按钮开关的使用寿命?

嵌入式按钮开关的使用寿命可能受某些因素影响,这些因素会降低其性能或缩短使用寿命。.

以下是部分影响因素及相应的解决建议。.

- 温度

- 嵌入式按钮开关在超出制造商建议的温度范围内使用。.

- 请参考制造商的温度规格,例如-20°C至+55°C。.

- 湿度

- 嵌入式按钮开关与环境不兼容。.

- 可选用能耐受潮湿环境的金属嵌入式按钮开关。.

- 空气污染

- 嵌入式按钮开关暴露在污染的空气中,有害物质可能与其材料发生化学反应。.

- 也可选择具有防污染特性的金属嵌入式按钮开关,以抵抗有害化学物质的侵蚀。.

- 振动

- 嵌入式按钮开关安装在持续振动的表面上,可能导致其部件松动或脱落。.

- 应选用能承受反复振动的防破坏型嵌入式按钮开关。.

- Frequency of use

- 嵌入式按钮开关无法适应日常使用频率而发生故障。.

- 最好选择坚固耐用、适合频繁使用的防破坏型嵌入式按钮开关。.

- 对执行器施加的力度

- 嵌入式按钮开关在未设计承受的情况下受到过大力度。.

- 同样,防破坏型嵌入式按钮开关是应对此类情况的不错选择。.

此外,注意为嵌入式按钮开关提供正确的电流,例如12V嵌入式开关仅需相同电流供电。.

请记住,制造商已开发多种类型的嵌入式按钮开关以解决各类问题。.

因此,需根据具体应用环境选择合适的嵌入式按钮开关类型。.

人行横道按钮

22. 应按下嵌入式按钮开关多深才能正常触发?

一般而言,触发嵌入式按钮开关仅需按下3mm至5mm(具体取决于类型),且通常仅需约3N至5N的力度。.

然而,需了解以下特定操作特性以理解为何单纯按压开关可能无效:

- 自由位置——执行器未受外力作用的状态。.

- 操作位置——执行器移动触点并完全触发开关的状态。.

以下力度影响嵌入式按钮开关的执行器:

- 操作力——使触点移动或瞬间切换所需施加在执行器上的力度。.

- 全超程力——用户施加最大压力使执行器超越行程的力度。.

- 释放力——从触点移动或切换至操作位置后,执行器返回自由位置过程中所受的力度。.

以下定义执行器的行程位置:

- 预行程位置——从自由位置到操作位置但不触发开关的移动距离。.

- 差动行程——执行器从触点开始移动或切换点起的行程。.

- 总行程——从执行器自由位置到超程位置的整体移动距离。.

23. 处理嵌入式按钮开关时通常遇到哪些问题?

有时我们购买的嵌入式按钮开关会出现不可避免的问题,甚至可能是由我们自身操作引起的。.

值得庆幸的是,在正确指导下部分问题可以修复。.

以下是处理嵌入式按钮开关时常见的一些问题:

- 尺寸不匹配

- 遗憾的是,有些人订购了错误尺寸的嵌入式按钮开关,往往选择弃用并重新购买。.

- 如果尺寸过小,可使用橡胶密封圈填补面板与开关间的空隙,或使用标签板覆盖。.

- 如果尺寸大于安装孔,最佳解决方案是尽可能使用孔锯扩大孔径,或改用独立的按钮开关站。.

- 开关后端脱落

- 这通常因安装孔过大、安装法兰松动或塑料外壳老化导致。.

- 检查嵌入式按钮开关是否完好,重新安装在尺寸合适的新孔位上,确保安装孔大小精确且安装法兰紧固。.

- 若塑料外壳已老化,可能需要更换整个开关。.

- 引脚熔化

- 这通常因烙铁温度过高或接触引脚时间过长导致熔化。.

- 可将焊台温度设定在370°C左右作为起始点,并在2至3秒内完成线缆与端子的焊接。.

- 同时,应瞄准引线而非端子进行焊接,避免直接接触端子。.

- LED指示灯不亮

- 这种情况通常发生在嵌入式按钮开关接线错误或LED使用寿命已结束时。.

- 检查接线是否正确,如有必要请重新接线。.

- 如果故障与接线无关,您可能需要维修或更换嵌入式按钮开关。.

24. 为何应选择高品质嵌入式按钮开关?

高品质嵌入式按钮开关不仅设计优雅美观,还能兼容各种应用并耐受恶劣环境。.

它们可能不是市场上价格最低的按钮开关,但其价格体现了与其品质相符的价值。.

选择高品质嵌入式按钮开关还能获得以下廉价替代品不具备的特性:

- 外观精美

- 更长使用寿命

- 应用场景广泛

- 满足各类应用需求的不同选项

- 维护需求低

- Easy to install

- 更长的产品保修期

- 适用于户外、含盐、潮湿等多种环境.

船舶控制系统

25. 如何确保嵌入式按钮开关具备高品质?

选购嵌入式按钮开关时,人们常通过产品名称、图片和价格来判断其品质优劣。.

然而在选择高品质嵌入式按钮开关时,还需关注以下重要因素:

- 产品描述

- 产品描述可帮助您深入了解产品的技术规格、类型、尺寸、特性、额定值等信息。.

- 务必仔细阅读以避免选购错误类型的嵌入式按钮开关。.

- 良好的客户评价

- 优质客户评价能反映产品品质及制造商的企业信誉。.

- 价格合理

- 通过阅读产品特性与质量标准认证,确保物有所值。.

- 查看图片和宣传视频

- 图片应具备高分辨率,以便放大检查嵌入式按钮开关的各个部件。.

- 若有相关视频,请花时间观看以了解开关的动态工作状态。.

- 寻找质量标识与认证

- 检查嵌入式按钮开关是否具有以下代表优质产品的认证标识:

- 防水防尘特性需寻找IP65、IP68或IP69K认证。.

- 防破坏特性需寻找IK10认证。.

- 检查嵌入式按钮开关是否具有以下代表优质产品的认证标识:

还可关注国际安全与环境标准认证,如ISO、CE、REACH符合性证书、RoHS、TUV和UL。.

国际标准与质量认证标识

26. 如何确保嵌入式按钮开关经久耐用?

若需确认嵌入式按钮开关的耐用性,可寻找IK10认证标识。.

IK10是嵌入式按钮开关外壳所能提供的最高防护等级。.

具备此认证的开关表明该型号已在不同温度条件下通过系列冲击测试。.

测试包括夏比冲击试验和落锤冲击试验。.

IK冲击测试等级从00至10,最高等级为IK10。.

通过最高等级测试的嵌入式按钮开关即为IK10级。.

IK10认证标识

27. 选购防水型嵌入式按钮开关需注意什么?

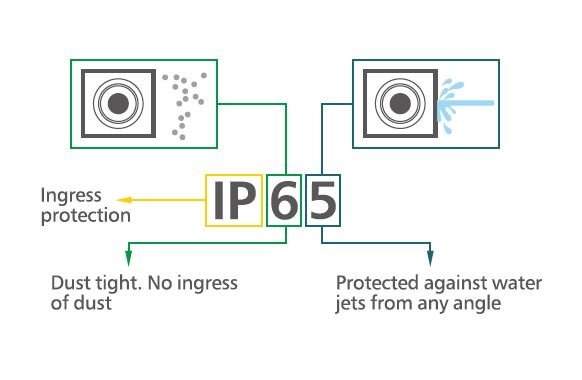

选购防水型嵌入式按钮开关必须关注IP防护等级标识。.

若无IP等级标识,则表明该开关不具备防水功能。.

IP防护等级标识是嵌入式按钮开关具备防水防尘性能的保证。.

它显示开关外壳对液体渗透及固体异物/颗粒的防护强度。.

等级数值越高,防护性能越强。.

IP代码首位数字表示防固体等级,第二位数字表示防水等级。.

若嵌入式按钮开关标有IP65、IP68或IP69K等级,说明其具备良好防护性能。.

IP65等级说明

28. 收到故障嵌入式按钮开关如何处理?

制造商会对每批开关进行专项质检,但偶尔仍有瑕疵品被疏漏并售出。.

收到故障开关时,需核查产品是否附带保修信息。.

通常所有制造商都会提供一定年限的保修服务,并明确保修涵盖的故障类型。.

应立即联系制造商协商更换或维修事宜。.

虽然最终决定权在制造商,但多数情况下收到故障产品后可安排更换。.

人为失误导致的损坏可能需要承担维修费用。.

维修或更换周期取决于您与制造商的地理距离。.

需注意:故障开关往往源于低劣的制造质量。.

因此选择生产高品质嵌入式按钮开关的可靠制造商至关重要。.

若您不确定如何选择,本常见问题指南已包含确保选购高品质开关的参考方法。.

嵌入式按钮开关测试

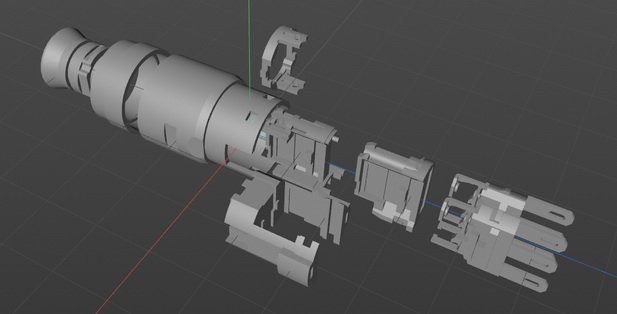

29. 是否只能选择市面现有类型的嵌入式按钮开关?

当然不是,您并不受限于当前市场上的开关类型。.

现代制造商的优势在于,部分厂商提供多样化定制选项,以满足您个人或商业应用的特殊需求。.

If you require a flush mount push button switch with specific shape, size, color, or design, you may coordinate with your manufacturer regarding their customization options.

You can collaborate on the desired specifications for your flush mount push button switches and explore additional available options.

You may also request specific technical specifications needed for your flush mount push button switches.

In addition to the aforementioned, some manufacturers offer various actuator designs and logos, and may accept 3D rendered designs of your preferred flush mount push button switch.

Example of push button switch 3D drawing