Langir面板安装按钮开关为您提供支持

Langir Electric是中国值得信赖的面板安装按钮开关生产商。Langir按钮开关通常安装在面板上,最大面板厚度为12mm。这意味着如果您的面板厚度小于12mm,您可以自由安装按钮开关。.

Langir面板安装按钮开关具有长电气寿命且易于安装。此外,快速断开功能和易清洁功能提高了我们产品的可靠性。.

Langir欢迎任何可能性的定制

Langir面板安装按钮开关可用于多种应用,包括工业控制。.

Langir面板安装按钮开关提供全系列产品,包括防破坏按钮、压电按钮开关和电容式感应开关。.

定制您的面板安装按钮开关也是可行的。事实上,我们提供多种面板安装按钮开关供您选择。.

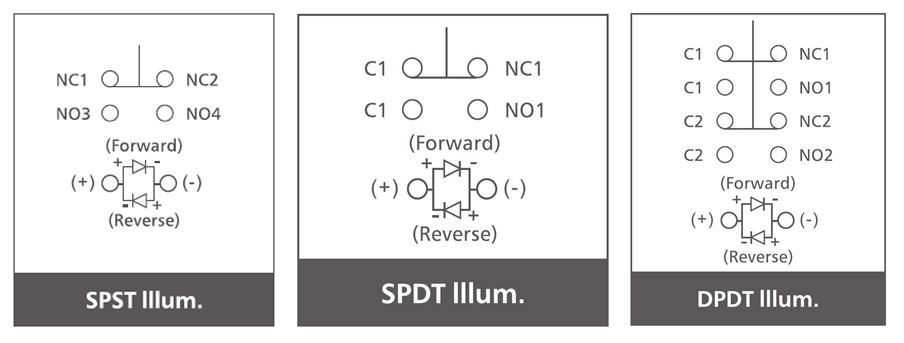

从功能、头部类型、照明或您喜欢的颜色,我们拥有您可能需要的一切。您可以定制具有以下功能的面板安装按钮: NO, NC,, SPDT, DPDT, ,或 SPST 按钮开关。.

您还可以将面板安装开关定制为您喜欢的齐平执行器。在Langir,我们可以为您提供非照明型、点状照明或环形照明的产品。.

所有这些都可以是双色或三色的。或者如果您想要单色照明,您也可以从我们现有的颜色中自由选择,如黄色、橙色、红色、蓝色、绿色和白色。.

如果您无法确定所需面板安装按钮开关的特性,我们的专家可以帮助您细化到每一个细节。与我们分享您的概念,我们将为您打造出符合您偏好设计和规格的实际产品。.

Langir仅遵循高质量标准。因此,我们所有的面板安装按钮开关都耐用、易清洁且易于安装。.

- Factory

- Application

FAQ’s

是的,Langir面板安装按钮开关质量上乘。.

最好小于12mm。.

是的,Langir面板安装按钮开关有6种LED颜色,如绿色、白色、蓝色、红色、黄色、橙色。.

孔公差不超过0.3mm

是的,它易于安装。.

如果您将开关安装在面板上,O型圈可以防止水进入机器或设备内部。.

Langir面板安装按钮开关

Langir Electric是中国值得信赖的面板安装按钮开关生产商。Langir按钮开关通常安装在面板上,最大面板厚度为12mm。这意味着如果您的面板厚度小于12mm,您可以自由安装按钮开关。除非您仅需美观效果,否则不能将其安装在不平整的面板上。这也被称为 表面安装.

Langir建议孔尺寸公差不超过0.3mm。例如,如果按钮开关为19mm,当您在面板上开孔时,孔径应约为19.3mm,这样水就不会渗入机器。O型圈将防止渗水。.

Langir面板安装按钮开关可选择常开、常闭、, SPST、SPDT或DPDT. 。齐平执行器提供非照明型、点状照明、环形照明、双色和三色照明,照明颜色可选择红色、黄色、绿色、蓝色、白色和橙色。因此您可以找到所需的确切选项。.

Langir面板安装按钮开关具有长电气寿命且易于安装。此外,快速断开功能和易清洁功能提高了我们产品的可靠性。总之,Langir面板安装按钮开关是您机器中非常易于使用的工具。.

浏览我们的网站或致电Langir,我们的销售团队随时准备为您提供帮助。您将获得我们快速且专业的报价!

面板安装按钮开关——常见问题指南

在本常见问题指南中,您将了解到关于面板安装按钮开关的许多有趣信息。.

您将了解到它提供的不同类型、可用颜色、形状和尺寸,这些在您阅读本指南之前可能并不熟悉。.

此外,您还将了解到关于面板安装按钮开关的各种重要信息,这些信息对其应用和使用将非常有用。.

因此,在购买面板安装按钮开关之前,您应该先阅读这份有用的常见问题指南。.

1. 什么是面板安装按钮开关?

面板安装按钮开关

面板安装按钮开关通常指开关的安装方法或将要安装的材料。.

它也有多个名称,如面板安装按钮、按钮面板、面板安装开关、按钮开关面板、按钮开关面板安装、面板安装按钮、按钮面板安装、开关面板安装,以及平头按钮或平头按钮开关。.

与其他类型的按钮开关类似,面板安装按钮开关也有不同类型、特性、功能以及许多其他分类,这使其成为适用于任何目的和应用的通用且可靠的选择。.

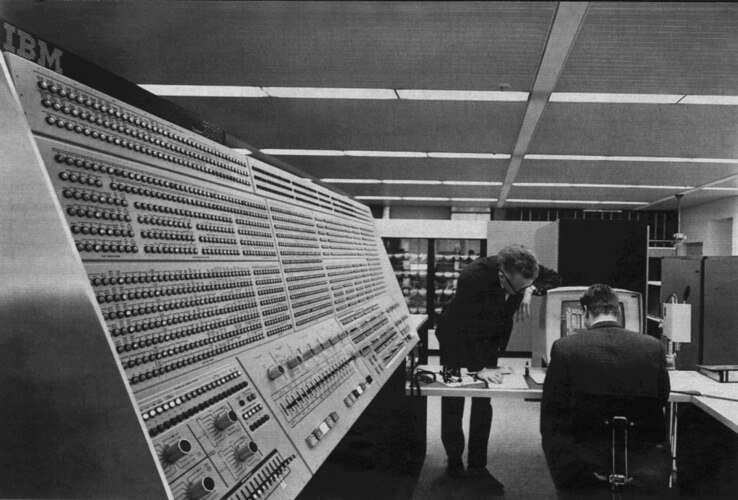

关于面板安装按钮开关使用的最早记录之一是20世纪60年代的早期计算机。.

早期计算机面板包含指示灯、刻度盘、符号显示器、控制台打字机、示波器、拨动开关以及安装在金属面板上的面板安装按钮开关的某些或随机组合。.

早期使用面板安装按钮开关的计算机之一是IBM的System/360 Model 91,用于其乱序执行,以与控制数据公司的CDC 6600竞争。.

System 360 Model 91前面板

2. 面板安装按钮开关的机制如何运作?

The panel mount push button switch operates to connect or disconnect one or more circuits that initiate the device or equipment function.

It requires manual force, such as pressing or touching the actuator, to move the internal mechanisms of the switch, thereby opening or closing the circuit and controlling the current flow.

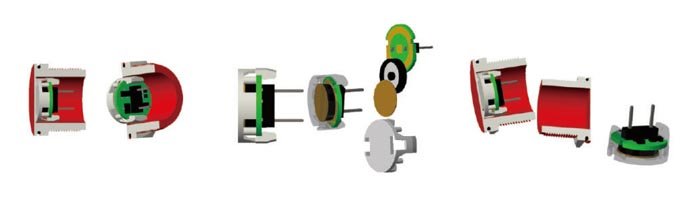

What constitutes the assembly of a panel mount push button switch?

The panel mount push button switch consists of two main components: the actuator and the body or enclosure.

However, besides these main parts, other components are equally important for the operation of the panel mount push button switch.

The following are the most common assembly parts of a panel mount push button switch:

- Actuator – Also referred to as the panel mount button, operator, or head, it is the user-facing part of the switch that is pressed to initiate the designated operation.

- Enclosure – Also known as the shell or body, it houses and protects the internal mechanical and electrical components of the switch.

- Terminals – Also called pins, these are the points where wires are typically connected to the switch.

- Mounting flange – Generally a hex-shaped nut used to fasten and secure the panel mount push button switch in place.

- O-Ring – Also known as a rubber ring or rubber seal, it is positioned beneath the actuator to seal the panel cutout and prevent water ingress when mounted.

- Grooves – These are indentations around the body of the switch that allow the mounting flange to fasten it tightly.

The interior of the panel mount push button switch contains a spring, fixed and movable contacts, and an LED chip for illumination.

Some types of panel mount push button switches, such as piezo switches, have no moving parts and instead contain an assembly module.

Piezo panel mount push button switch components.

What types are considered panel mount push button switches?

The term "panel mount push button switch" is a general designation for any push button switch installed in a panel.

This means there is a wide variety of types and designs available.

The following are some varieties of panel mount push button switches available on the market today:

- Flat head panel mount push button switch.

- Panel mount switch with LED.

- Red LED panel mount push button switch.

- Panel mount power switch.

- Waterproof panel mount switch.

- Anti-vandal panel mounted switch.

- Piezo panel mounted switch.

- Capacitive panel mounted switch.

- Miniature panel mount push button switches.

- Low profile panel mount push button switch.

Low profile panel mount push button switch.

What are the various characteristics of a panel mount push button switch?

Panel mount push button switches have different characteristics, such as diameter sizes, colors, actuator shapes and designs, terminals, and more.

The following table illustrates the different characteristics of panel mount push button switches:

| Diameters | Colors | Actuators | 内部机制 |

| 10毫米 | 黑色 | 平头 | Solder lug |

| 12毫米 | Green | Raised. | Screw type |

| 16毫米 | White | 方头 | Wire leads |

| 19毫米 | Orange | Ring symbol | Feed-through style |

| 22毫米 | Amber | Power symbol | Quick connector blade |

| 25毫米 | Chrome | Ring and power symbol | |

| 30毫米 | Red | Laser etched head | |

| Yellow | 带照明 | ||

| Blue | Non-illuminated | ||

| 灰色 | |||

| Ivory | |||

| Gold |

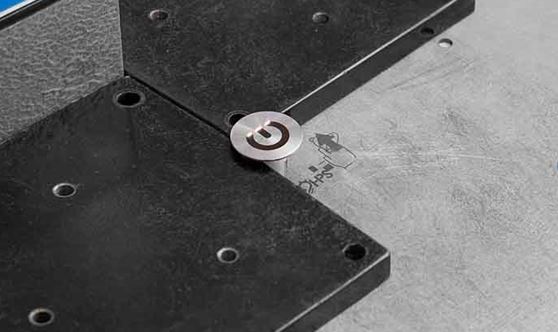

Panel mount push button switch laser head.

What are the styles and purposes of panel mount push button switches?

Panel mount push button switches are also classified by style and purpose.

This classification addresses issues such as accidental button presses by stray fingers or activation by objects inadvertently bumping into the switch.

This solution is particularly important when the switch's purpose relates to security, safety, and critical processes.

- Extended application.

- The actuator is raised higher compared to other standard raised button heads.

- Typically used for the “stop” function in machinery.

- Flush application.

- The actuator is flush with its enclosure, meaning direct pressure is required to actuate the switch.

- Commonly preferred for “start” functions, such as in push-button start panels.

- Selector switches application.

- Used when multiple control options are required.

- Employed for maintained contact applications.

- Guarded application.

- This further prevents unwanted operation, as the actuator is surrounded by a metal guard.

- Mushroom and Jumbo mushroom application.

- These are generally used for emergency stop and stop push buttons.

- They are very easy to operate, making them ideal for emergency situations.

- Push-pull operators.

- The actuator must be physically pushed and pulled to turn the switch off and on.

- Typically used for two-position maintained contacts (e.g., start/stop or up/down buttons) or three-position maintained or momentary contacts (e.g., start, stop, run buttons or hand, off, auto functions).

- Twist to release application.

- In this application, the actuator is activated by pushing it in and then twisting to release.

- Generally used for «emergency stop» or «stop» functions in machinery.

- Key release application.

- Similar to twist to release, but requires inserting a key to release the actuator.

- Often used for safety purposes, such as locking a machine during maintenance procedures.

- Illuminated lens or operator.

- This combines push-button functionality with an indicator light, saving space and cost for the user.

- Although the push-button and indicator light are integrated into one device, they are wired separately to function.

- Roto push application.

- This application combines the push button and selector switches in one device.

- The push button has an outer guard that can be rotated to multiple positions which can provide several contact actions whenever the actuator is pressed or released.

- Potentiometer

- This is often used as a control for speed since it can vary resistance by turning its dial.

- Joystick application

- The buttons are mounted in a standard hole size with some space left behind the panel for the lever to work.

- Square operator with multifunction application

- This is used when there are several functions required and space is at a premium.

Emergency stop push button switch

7. What are the switch actions of the panel mount push button switch?

The panel mount push button switch can be categorized into two different switch actions which are the following:

- Panel mount momentary push button switch – In this switch action, the actuator remains depressed while it is being pressed down and it springs back into its normal state when the pressure is released.

It is also called the panel mount momentary switch, panel mount momentary push button, panel mount momentary push button switch, flat momentary switch, and momentary switch panel.

- Panel mount latching push button switch – In here the actuator remains depressed even after releasing the pressure and will only return to its normal state when it is pressed again.

Momentary panel mount push button switch application

8. What are the switch starting positions of the panel mount push button switch?

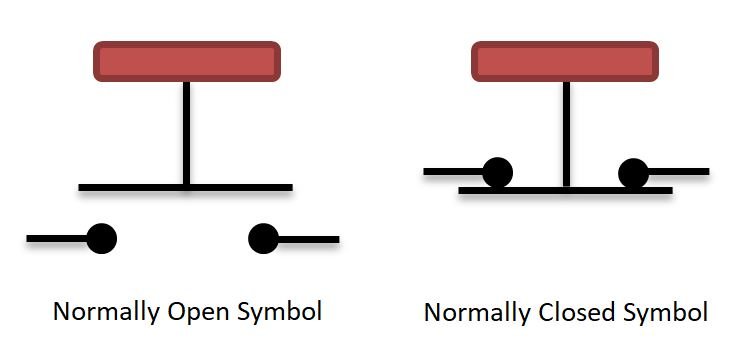

The panel mount push button switch momentary and latching switch actions have two kinds of starting positions or contact states, and they are:

- Normally open panel mount push button switch – In this starting position, the contacts are always open until the actuator is pressed down which connects the contacts and allowing the current flow.

- Normally closed panel mount push button switch- In here the contacts are always closed and the contacts are connected until the actuator is pressed down that disconnects them.

Some of the examples are the following:

- Off

- Off or On

- 1 Off (Normally Open)

- 1 Off (Normally Open) and 1 On (Normally Closed)

- 1 Off (Normally Open) or 1 On (Normally Closed)

- 1 On (Normally Closed)

- 2 Off (Normally Open)

- 2 Off (Normally Open) and 2 On (Normally Closed)

- 2 Off (Normally Open) or 2 On (Normally Closed)

- 2 On (Normally Closed)

- 3 Off (Normally Open)

Normally open and normally closed push button switch symbol

9. What are the electrical industry designations of the panel mount push button switch?

The panel mount push button switch also has electrical industry designations or in simple terms, electrical control circuit classifications or contact forms.

These are the poles and throws of the panel mount push button switch.

Most of the time, people tend to define the poles by the number of the switch’s terminals but this is not the definition of the term at all.

The poles refer to the number of circuits that a switch can control.

For example, a single pole controls one circuit, two poles control two circuits within one unit, and so on.

There are four basic contact form variations and these are the following:

- Single Pole Single Throw (SPST)

- This is also known as the two way switch or on and off switch.

- It controls the connection and disconnection of two terminals.

- It can only have one “on” position.

- For example, push button on off panel.

- Single Pole Double Throw (SPDT)

- This is also known as the A/B switch.

- This has one input terminal and two “on” positions.

- Double Pole Single Throw (DPST)

- Has the ability to control two circuits.

- There are two inputs and two «on» positions.

- Double Pole Double Throw (DPDT)

- Can control two electrical circuits with two input terminals and two selections for the output terminals.

- Can be configured as a single pole.

Electrical control circuit symbols for push button switches

10. Why do most panel push button switches are made from stainless steel?

Stainless steel is one of the iron-based alloys which contains some amount of chromium to make it rustproof and heat resistant.

Other types of stainless steel include some amounts of carbon, aluminum, nitrogen, silicon, titanium, sulfur, copper, molybdenum, niobium, nickel, and selenium.

Most panel mount push button switches are made from stainless steel and this is because stainless steel is a durable material.

There are over 150 stainless steel grades but panel mount push button switch manufacturers generally use two kinds of grades only which are grades 304 and 316.

- 304 stainless steel grade – This grade has some amount of nickel and chromium which makes it high temperature resistant and high density.

- 316 stainless steel grade – This grade has molybdenum included which makes it resistant to high temperatures and rust.

While stainless steel is the most preferred material for panel mount push button switches, other materials are also used such as the following:

- Anodized Aluminum

- Silver alloy

- Gold and nickel-plated brass

- Gold and silver-plated copper

- Silicone

- Ceramic

- 聚碳酸酯

- Nitrile

金属按钮开关

11. 面板安装按钮开关最适合哪些应用场景?

面板安装按钮开关广泛应用于各类设备、电子装置及众多不同行业的产品中,例如:

- 独立机器

- 所有工业机器通常都由面板安装按钮开关控制。.

- 工厂装配线

- 制造企业的装配线由面板安装按钮开关控制。.

- Airlines

- 登机桥通过面板安装按钮开关控制,可定位至正确位置并锁定在飞机舱门上。.

- 洗车业务

- 洗车操作员通过按压面板安装按钮开关来控制洗车流程。.

面板安装按钮开关的应用不仅限于上述行业,您还可以在家庭应用中找到它们,例如照明开关、车库门和门禁控制,以及DIY项目。.

面板安装按钮开关的应用

12. 前安装与后安装面板按钮开关有何区别?

前安装与后安装面板按钮开关在外观及安装方式上有所不同。.

| 前安装面板按钮开关 | 后安装面板按钮开关 | |

| 外观 | · 前安装面板按钮开关的执行器侧面带有凹槽,因为安装法兰固定于此位置。. · 由于安装法兰位于面板前部可见,因此外观更为美观。. | · 后安装面板按钮开关具有标准按钮开关的常规外观,开关本体周围设有用于固定安装法兰的凹槽。. · 这种安装方式提供了更好的表面间隙。. |

| 安装方法 | · 前安装面板按钮开关从面板后方插入,并通过开关前部的安装法兰固定。. · O型圈和安装法兰安装在面板前部的开关上。. | · 而后安装面板按钮开关从面板前方插入。. · 在将开关插入孔洞前,需先将橡胶圈穿过螺纹。. · 随后在面板背面将安装法兰紧固到开关上,以确保其牢固固定。. |

13. 为何30mm面板安装按钮开关首选前安装方式?

30mm面板安装按钮开关首选前安装方式,原因如下,或为许多行业带来以下优势:

- 安装过程简化。.

- 面板安装按钮开关的外壳防护等级得以保持。.

- 30mm切口设有卡口,可确保面板安装按钮开关固定到位,限制其在使用过程中的移动,同时安装法兰能实现更好的密封。.

- 无需打开面板即可更换面板安装按钮开关的灯泡或LED。.

- 零电弧闪光事故。.

- 与前安装方式相比,可在前部放置平面垫片以密封较大表面积。.

- 由于安装从背面进行,用户无需担心需在面板前放置铭牌、防护罩或锁闭装置等部件。.

- 可使用垫片来补偿不同面板安装按钮开关的厚度差异。.

- 用户或电工无需打开面板即可进行维修或维护工作。.

- 只需聘请一名专业人员即可完成维修或维护工作,而无需分别雇佣属于两个不同工会且不允许交叉作业的电工和机械师,从而节省专业服务费用。.

- 接触块直接固定在面板安装按钮开关上,无需任何固定环,这意味着分销商需订购和库存的零件编号更少。.

前安装面板按钮开关

14. 面板安装按钮开关的最大面板厚度是多少?

面板安装按钮开关的推荐最大面板厚度约为12mm。.

这意味着如果面板厚度为12mm,您可以毫无问题地安装面板安装按钮开关。.

然而,当面板表面不平时,您可能会遇到困难,密封效果可能不佳,并可能导致灰尘或水进入面板背面。.

15. 面板安装按钮开关允许的测量误差是多少?

为面板安装按钮开关开孔时,偶尔会出现测量误差。.

这可能导致外壳周围留有一些间隙,使得安装略显松动。.

建议仅允许0.3mm的测量误差,且尽可能不超过此值。.

因此,如果您有一个16mm的面板安装按钮开关,面板孔的最大直径应仅为16.3mm。.

否则,水可能渗入面板,导致机器损坏。.

16. 面板安装按钮开关的接触块有何作用?

有时您会在面板背面看到接触块和照明单元。.

它们负责电路连接,使机器能够启动、停止或运行。.

如果面板安装按钮开关带有指示灯,灯光信号指示机器运行的当前阶段。.

按钮开关接触块示例

17. 带指示灯的面板安装按钮开关有哪些优势?

带指示灯的面板安装按钮开关有助于您:

- 了解机器、设备或装置是否处于“开启”或“关闭»状态以及其他状态。.

- 通过颜色编码的灯光即时了解开关的用途。.

- 拥有耐用的指示灯,从而节省更换成本和人工服务费用。.

18. 如何在面板上正确安装面板安装按钮开关?

在面板上安装面板安装按钮开关时,务必全程遵循指导,以确保安装正确,避免重新安装或测量误差,从而浪费优质面板材料。.

开始安装前,您需要准备以下工具和材料:

- 一个面板安装按钮开关

- 面板开孔

- 面板板材

- 开孔器

- 焊接工具

以下是面板安装按钮开关的安装步骤指南:

- 在面板板材上描绘开孔轮廓,并使用孔锯进行切割。.

- 将面板安装按钮开关试装入孔中,以确保其贴合度适中。.

- 在下一步之前,先将O型圈安装到面板安装按钮开关上。.

- 随后参照接线指南,将导线焊接到面板安装按钮开关的端子上。.

- 接着将面板安装按钮开关穿过面板孔进行安装。.

- 取安装法兰,在面板背面将开关妥善固定。.

- 连接导线并测试面板安装按钮开关。.

19. 面板安装按钮开关的一般使用寿命是多久?

面板安装按钮开关的使用寿命取决于其质量和使用方式。.

高质量的面板安装按钮开关通常具有约1,000,000次机械寿命周期和约200,000次电气寿命周期。.

而质量较差的面板安装按钮开关的机械和电气寿命周期可能较低。.

除了质量因素外,有时面板安装按钮开关若被用于超出其设计目的、容量或制造商建议的范围,其使用寿命也会缩短。.

例如,将不防水的面板安装按钮开关用于近水环境。.

在此类条件下,最好使用 防水面板安装按钮开关。.

另一个例子是在高使用频率的应用中使用普通面板安装按钮开关。.

对于此类应用,强烈建议使用防破坏面板安装按钮开关,以确保强大的耐用性和长久的使用寿命。.

20. 面板安装按钮开关在应用中有哪些优势?

面板安装按钮开关提供诸多优势,使您的投资更具价值,部分优势列举如下:

- 持久耐用

- 引人注目的美观性

- 适用于多种应用

- 广泛的类型和设计选择

- 节省空间的选项

- 价格合理

- 快速断开功能

- 易于清洁

- 维护需求低

- 可安装于多种环境条件下,例如:

- 多尘环境

- 冲洗环境

- 潮湿环境

- 含盐环境

- 腐蚀性环境

- 油污环境

- 户外环境

- 潜水环境

- 高压冲洗环境

- 危险环境

由于面板安装按钮开关卓越的质量和多功能特性,它被广泛认为是任何开关应用的最佳选择。.

潜水防水面板安装按钮开关

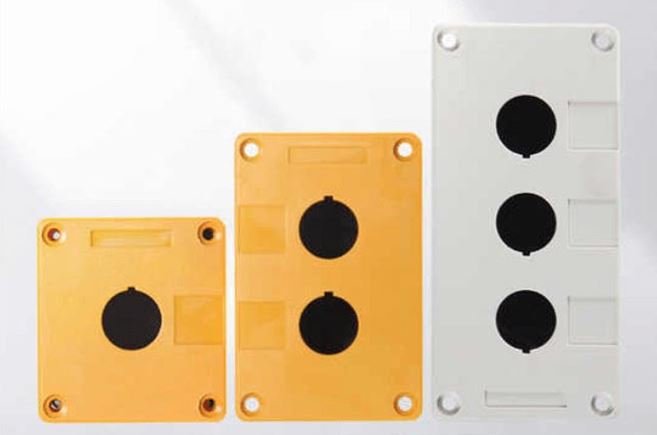

21. 什么是面板安装按钮开关站?

这是指按照矩阵或排列方式集中安装在一个面板上的多个面板安装按钮开关。.

面板安装按钮开关可在单个面板或按钮控制面板中定制为不同功能。.

一个站台容纳多个面板安装按钮开关可节省空间,因为无需使用多块面板板材,从而也节省了成本。.

按钮开关站

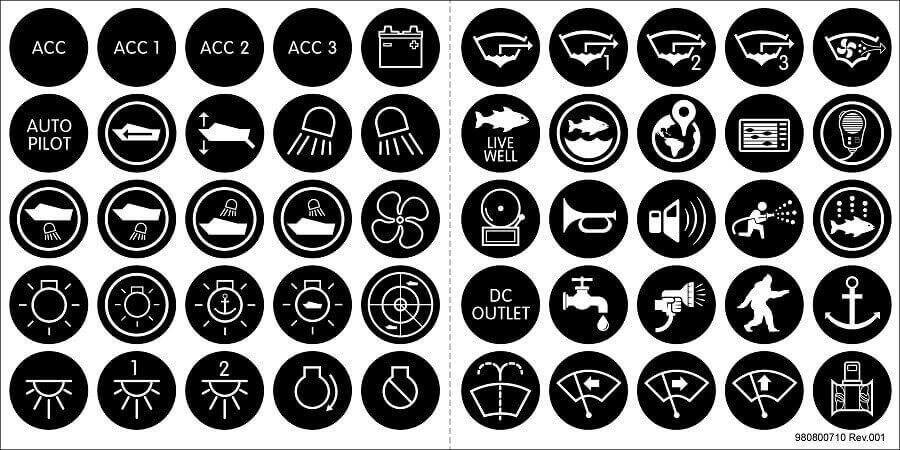

22. 什么是面板安装按钮开关标识牌?

面板安装按钮开关标识牌可帮助您立即识别特定功能对应的按钮。.

这也有助于避免因人为错误而按错按钮,从而导致后续问题。.

这些是小型标识牌,具有不同的颜色和尺寸种类,如下例所示:

- 标准标识牌 – 通常紧密贴合在面板安装按钮开关周围。.

- 超大标识牌 – 这些是外观醒目的标识牌,通常用于«停止»功能,且常为红色。.

按钮开关标识板

23. 面板安装按钮开关的常见问题有哪些?

了解面板安装按钮开关的常见问题是非常有用的信息,可帮助您在选购或安装时做出决策。.

- 空间问题

安装面板安装按钮开关时,有时可能没有足够的空间供您操作双手进行轻松安装。.

因此,制造商会提供定义垂直和水平尺寸的安装矩阵图。.

- 外壳

一些复杂的机器需要多个面板安装按钮开关,这意味着您还需要不同尺寸的外壳,以为电线、电缆和导管提供足够空间。.

您还需要考虑面板安装按钮开关在面板后方占用的空间,因为它们的长度各不相同。.

了解这些信息可确保外壳有足够的深度容纳所有开关。.

您还需要确保外壳符合侵入保护和环境防护等级,如NEMA、UL和IEC IP等级,这些等级涉及防尘、防水、防油和防振保护。.

- LED使用寿命

对于LED很少点亮的面板安装按钮开关,可以使用较短灯寿命的产品,或者省略LED的接线。.

然而,对于频繁使用的应用,最好选择高质量的LED面板安装按钮开关。.

24. What does the IK seal mean in panel mount push button switches?

Sometimes you may see a seal labeled IK10 in the product description or packaging of a panel mount push button switch.

This seal indicates the level of protection that the enclosure of the panel mount push button switch provides against specific degrees of mechanical impact and harsh temperature conditions.

Manufacturers subject their panel mount push button switches to two types of IK impact tests: the Charpy impact test and the drop weight impact test.

Each test involves different levels of impact and varying temperature conditions to simulate challenging environments.

Based on the performance of the panel mount push button switch during testing, it is rated from IK0 to IK10, with IK10 being the highest rating.

IK10认证标识

25. What does the IP number mean in panel mount push button switches?

The IP number seen in the description of a panel mount push button switch refers to its level of protection against solid particles and water ingress, where IP stands for Ingress Protection.

The two-digit numbers represent the levels of protection against solids and water, respectively.

The first digit indicates the degree of protection against solid ingress, while the second digit indicates the degree of protection against water ingress.

This also means that the panel mount push button switch undergoes two types of testing: solid particle protection testing and water ingress protection testing.

Each test consists of a series of procedures to determine the maximum level of protection the panel mount push button switch can withstand without damage.

After these tests, the panel mount push button switch is assigned a rating ranging from IP11 to IP69K.

Examples include marine push button switch panels or push button marine switch panels.

IP rating seals for water-resistant and waterproof push button switches

26. How to select a high-quality panel mount push button switch suitable for any application?

When searching for a panel mount push button switch, it is essential to understand the details that will help you determine whether it is of high quality and suitable for your intended application.

Here are some factors to consider when looking for a high-quality panel mount push button switch:

- Positive customer reviews

- If the panel mount push button switch has favorable customer reviews, it generally indicates good quality.

- Customer reviews are often found on the manufacturer’s website, online marketplaces, vendor sites, product brochures, and similar platforms.

- Appropriately priced

- The price is often the first thing noticed in a product listing and can significantly influence the purchasing decision.

- Sometimes, a low price may indicate inferior quality, but this does not necessarily mean that higher-priced panel mount push button switches are of high quality.

- Compare the prices of several panel mount push button switches to identify a reasonable price range.

- Review images and demo videos

- While most product listings include images of the panel mount push button switch, having a demo or promotional video can be more informative.

- If the product listing does not include videos, try visiting the manufacturer’s website or their YouTube channel.

- Analyze the images and videos of the panel mount push button switch to determine if it meets your requirements.

- Check for quality seals

- As a consumer, you should look for markings or seals that indicate the quality of the panel mount push button switch.

- Some of the seals to look for include:

- IP65, IP68, or IP69K seals for waterproofing

- IK10 seal for vandal resistance

- Some of the seals to look for include:

For international safety standards, look for:

- ISO认证

- CE (European Conformity)

- REACH certificate of compliance

- RoHS (Restriction of Hazardous Substances)

- TÜV (Technical Inspection Association)

- UL (Underwriters Laboratories)

国际标准与质量认证标识

27. What if you receive a faulty panel mount push button switch?

Occasionally, you may receive a faulty panel mount push button switch despite the manufacturer’s quality checks.

In such cases, it is best to secure the warranty documentation, which should accompany the product or be sent to you via email.

The warranty documentation will specify the duration of coverage and the details of what is covered.

Generally, if you discover that the panel mount push button switch is not working shortly after receiving it, you can contact the manufacturer or vendor immediately to request a replacement.

Testing the panel mount push button switch upon receipt is crucial in such situations.

If you store it first, you may forget about it until the warranty expires and may no longer be eligible for a replacement.

Replacement of a faulty panel mount push button switch with a new one is subject to the manufacturer’s discretion.

If the panel mount push button switch has already been used, the manufacturer’s repair technician will diagnose the issue, and this assessment will determine the applicable warranty policy.

If the fault is due to human error, it may not be covered by the warranty, and you may be charged repair fees.

Additionally, the time required for repair or replacement can take several weeks, depending on your location.

Therefore, it is advisable to test the panel mount push button switch before installation to ensure it is in good condition and avoid future issues.

It is also worth noting that if this occurs, the panel mount push button switch you purchased may not be of good quality.

So, the next time you shop for panel mount push button switches, always look for the high-quality features outlined in this FAQ guide.

28. How to test a panel mount push button switch to determine its condition?

It is important to test the panel mount push button switch as soon as you receive it.

This helps determine whether it is a functional or defective switch before you begin working with or installing it.

To check the condition of the panel mount push button switch, use a multimeter for testing.

- First, check the multimeter’s condition by turning it on and adjusting the range selector knob.

- Connect the test leads to the appropriate ports for testing.

- The black lead goes into the COM port.

- The red lead goes into the current port for voltage measurement or the MaV Ω port for resistance measurement.

- Test the leads first by touching the probes together.

- The multimeter display should show approximately 1 ohm.

- If not, check whether the leads are correctly connected to the appropriate ports; otherwise, the multimeter may not be functioning properly.

- Then using the probes, touch the panel mount push button switch’s terminals with one probe in one terminal.

- The display will show 1 ohm or less and OL if the panel mount push button switch is off.

- After this multimeter testing is done, you can be sure that the panel mount push button switch is in good working condition and ready for installation.

29. Can you request modifications for your panel mount push button switch order?

Yes, you can of course.

Some manufacturers welcome modifications or customization requests from their customers and clients regarding their panel mount push button switch orders.

Whether you need a unique-looking panel mount push button switch, or a specific color or size, you can bring this up to your manufacturer and know if these modifications are possible.

You may also be provided with other customization options that are available that you may find interesting and will surely help your customization goals.

Here are some of the options that may be available for your panel mount push button switch’s modification request:

- The kind of materials which are going to be used for making the panel mount push button switch

- The diameter size and measurements of other parts.

- The shape and color of the panel mount push button switch

- The design and type of the actuator whether it is illuminated or not

- Backlit logo options

- Other specifications you need for your panel mount push button switch

If you have your panel mount push button switch design such as 3d rendered illustrations, you can also consult your manufacturer about the possibility of considering it for your orders.

You should also confirm with your manufacturer if they have a minimum quantity requirement for modification requests.

Symbol options