按钮和急停按钮是工业与控制系统中最常用的两种组件,但二者有何区别?何时应选用其中一种而非另一种?本文将分别阐述其定义、常见用途,并详述其在结构形式、功能应用及规范标准方面的主要差异。.

Push Button Switch

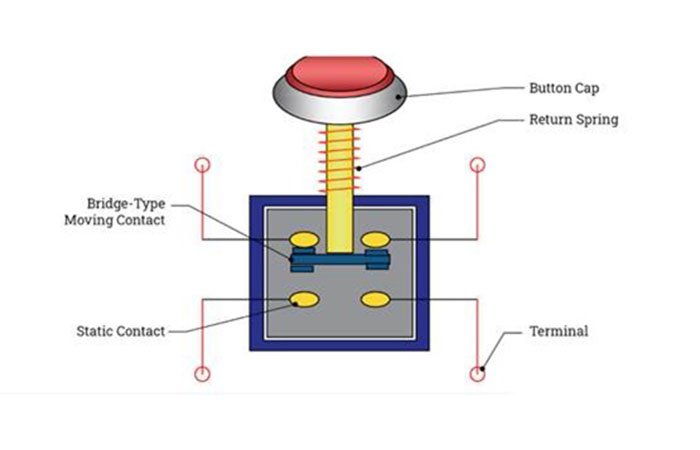

A A push button switch A switch that completes or breaks an electric circuit when actuated by pressing a button. It is used for momentary contact and is an input device.

Types of Push Button Switches

- Momentary Contact: A switch that is turned on only as long as the button is held down (for example, a doorbell).

- Latching/Maintained Contact: The switch maintains its actuated position unless acted upon again (for example, a light switch).

- NO (Normally Open): Contacts are open when at rest and are closed when power is applied.

- NC (Normally Closed): Contacts are closed when not pressed and open when pressed.

- Illuminated: Contains a built-in indicator light for checking status.

- Non-Illuminated: No built-in light.In industrial control panels, they are critical for tasks such as starting and stopping motors, activating conveyors, and opening or closing valves. Beyond industry, they are key components in consumer electronics—including on-off switches, volume control dials, and input keys. They are also found in everyday household appliances like washing machines and microwaves, as well as in automotive applications for operating windows and activating the horn.

Typical Applications

Emergency Stop Button (E-Stop).

An E-stop button is a safety switch designed to quickly and safely halt machinery, equipment, or processes in control systems during an emergency. Its primary purpose is to manage risk and reduce the potential for damage or injury by forcing equipment into a safe state as rapidly as possible. It serves as an immediate intervention to prevent hazardous situations. E-Stop buttons incorporate specific safety features:

Dominant Color and Shape: Typically red, mushroom-shaped, and easily recognizable.

Key Characteristics and Design Principles

Latching: Once activated, the button remains engaged until manually reset, ensuring the hazardous condition is addressed.

- Positive Breaking Contacts: In the event of contact welding during a fault, the E-Stop mechanism forcibly separates the contacts to break the circuit, a critical safety function.

- Tamper-Proof: Designed to prevent accidental or unauthorized activation or deactivation.

- Fail-Safe Construction: Engineered to return to the off position even if the actuator fails, ensuring a safe shutdown.

- E-stop buttons are governed by stringent international and national safety standards, such as ISO 13850 (EN 418) and IEC 60204-1. These regulations define their construction, placement, and operation to maximize effectiveness during emergencies.

- E-stops are mandatory in applications where machinery poses potential hazards. Examples include:.

Standards and Regulations

Factories: Robotic arms and heavy machinery on production lines. OSHA Conveyors: For immediate stoppage in cases of entanglement or abnormal conditions.

Emergency Stop Button Applications

Automated Warehouses: Forklifts and AGVs (Automated Guided Vehicles).

- Process Industries: Chemical plants and power plants.

- Machine Tools: Lathes, milling machines, and presses.

- Design/Appearance Colorful, typically robust and flush-mounted.

- Distinctive red mushroom head, often with a yellow background.

- Optional (momentary or maintained action).

Push Button Switch VS Emergency Stop

| Feature | Push Button Switch | An E-stop button is a safety switch designed to quickly and safely halt machinery, equipment, or processes in control systems during an emergency. Its primary purpose is to manage risk and reduce the potential for damage or injury by forcing equipment into a safe state as rapidly as possible. It serves as an immediate intervention to prevent hazardous situations. |

| Presses in and latches; requires manual reset | Standard NO/NC contacts | Guaranteed circuit breaking with positive contact opening |

| Latching Mechanism | Automatic (momentary) or manual (maintained) reset | Manual reset (via twist, pull, or key) to enforce safety verification |

| Contact Operation | General electrical safety standards | Strict international safety standards and regulations (e.g., ISO 13850) |

| Reset Mechanism | E-stops feature a distinctive appearance to enable rapid identification and access during emergencies. Push buttons offer a wider variety of designs for both aesthetic and functional integration. | E-stops require a latching mechanism to maintain the safe state; without it, the system could restart if the operator releases the button. Standard push buttons may be latching or non-latching based on application needs. |

| Regulatory | E-stops must incorporate "positive opening contacts" as a safety requirement. This ensures the circuit breaks even if contacts weld under heavy loads or fault conditions—a feature not typically required for regular push buttons. | An E-stop includes a manual reset that requires deliberate effort, ensuring the operator acknowledges and addresses the issue before resuming operation. This prevents immediate restart of a potentially hazardous system. |

Design and Appearance

E-stop buttons are legally mandated in many industrial settings due to specific safety requirements. Push button switches fall under general electrical safety codes, not the same stringent, safety-specific regulations as E-stops.

Latching Mechanism

Selecting the correct component and ensuring proper installation are critical. Key factors to consider include:.

Contact Operation

First and foremost, verify that E-Stop buttons comply with applicable international and local safety standards. Incorrect selection can lead to serious accidents and legal repercussions.

Reset Mechanism

While safety is paramount, practical aspects must also be considered. For instance, a push button for pump control should be easily accessible to ensure operational ease and efficiency.

Regulatory

Regular testing of E-Stop buttons is essential to guarantee proper function during emergencies. This typically involves periodic functional tests as part of a comprehensive safety program. Push buttons also require maintenance for reliability, though their failure generally results in less severe consequences.

Correct Selection and Installation

Push button switches and emergency stop buttons differ in function, design, and regulatory standards. Both are vital in control systems, and confusing or misusing them can lead to operational inefficiencies or catastrophic safety incidents. Understanding these differences and adhering to proper selection and installation practices is key to ensuring safe and efficient industrial operations.

Safety Compliance

First and foremost, ensure that the E-Stop buttons are designed according to the applicable international and local safety criteria. Wrong selection may cause serious accidents and legal consequences.

Operational Efficiency

As much as safety first, you should also be thinking about the practical side of things. For easy access, a push button for controlling the pump ensures ease of use and handling.

Maintenance and Testing

Regular testing of E-Stop buttons is absolutely vital if they are to operate properly in the event of an emergency. This most frequently includes periodic functional tests, as implemented in a comprehensive safety program plan. Even the push buttons need to be maintained for their reliability. However, if they do fail, at least the damage is less dramatic.

Conclusion

The push button switch is different from an emergency stop button in terms of function, structure, and standard. Both of these elements are crucial in control systems, and confusing one for the other, or using them incorrectly, has potentially disastrous consequences including operational inefficiencies or catastrophic safety incidents. Knowing these differences and adhering to the correct selection and installation practices is key to ensuring safe and efficient industrial facilities.

FAQs

- Can E-stops be wireless?

Wireless E-stop buttons actually exist and are utilized in various industrial environments. They enable remote machine shutdown without compromising safety standards or compliance with transmission regulations.

- Is it a bad idea to use an emergency stop button for power, and if not, how?

An emergency stop button should not be used as a power button. E-stops are not intended for routine equipment cycling on and off.

- Can I use a general-purpose pushbutton switch as an E-Stop push button?

No, general-purpose push buttons cannot be used as emergency stop devices. Emergency stop devices must meet specific safety requirements, which ordinary push buttons do not satisfy.

- What does «positive opening contacts» mean with reference to an E-stop button?

«Positive opening contacts» refers to a fail-safe mechanical design where the contacts are forcibly opened by the actuator's motion to break the circuit, ensuring they cannot weld shut even during a fault. This is an essential safety feature of any genuine E-stop product.