This guide will explore O-rings, what they are and how they function, and how to choose the right material for your project. We’ll also examine important design considerations, typical modes, causes of failure, how to diagnose them, and best application and maintenance tips.

How O-Rings Work

An O-ring is a loop made of elastomer and has a circular cross-section that is used when sealing with more than one part. It must be inserted in the groove and compressed with these parts to create the sealing. It is intended to prevent fluid or gas leaks at the interface between the two mating surfaces. When squeezed, it deforms to bash out any imperfections and makes a reliable barrier.

Factors To Consider When Selecting an O-Ring

These are the critical things to consider when selecting an O-ring.

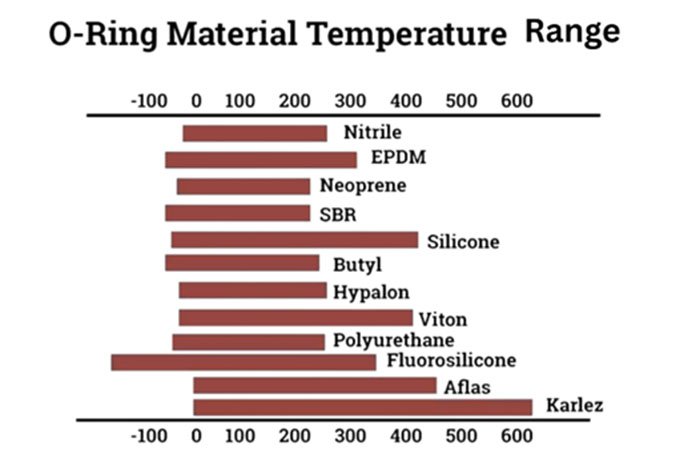

Temperature Range

Think about the O-ring’s high and low-temperature extremes. Some materials excel in extreme heat but turn brittle in the cold.

It is important that the material can withstand the entire range of operating temperatures to avoid embrittlement, cracking or softening, all of which affect the seal.

Pressure Levels

You must be able to differentiate between static and dynamic pressure resistance. Static seals are subjected to steady pressure, while dynamic seals are subject to fluctuating pressures and extrusion. More demanding applications would typically entail harder O-ring materials and the use of backup rings to prevent extrusion of the O-ring to fill clearance gaps.

Chemical Media Compatibility

Make sure that the O-ring material is compatible with all of the fluids or gases in your application. Think of acids, alkalis, oils, solvents, ozone, etc. If contact is made with incompatible materials, the O-rings will swell, shrink, harden , or soften, causing leakage. Always use chemical compatibility charts that are specific to O-ring elastomers.

Special Requirements

If your application involves food or medical contact, you’ll need food-grade or medical-grade materials that are tested to specific industry and regulatory standards. For exposure to the exterior, ozone and UV resistance materials are required. Suppose you expect a lot of rapid pressure changes, like in a high-pressure gas system. In that case, you’ll need to use material resistant to explosive decompression to prevent the o-rings from blistering and bursting.

Mechanical Properties

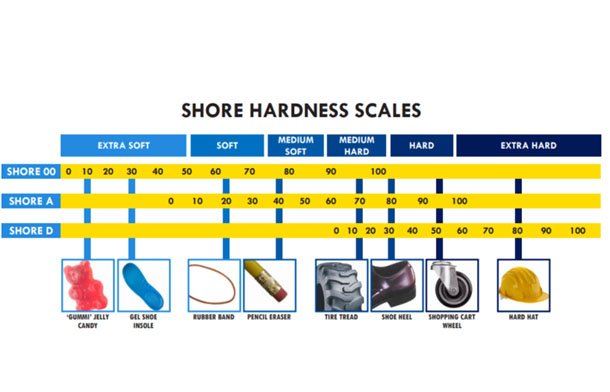

Durometer (Shore A hardness)

This measures the hardness of the material to help you predetermine compression and extrusion settings. O-rings are available in the standard 50 to 90 Shore A hardness range. This means softer materials (e.g., 50-70 Shore A) provide better sealing at low-pressure and conform more easily to irregular seal surfaces, though they are prone to extrusion at high pressures.

Harder durometers (80–90 Shore A) extrude less and wear better, which can be useful for high pressures and dynamic applications, but may need high sealing force and not seal as effectively against imperfections on sealing surfaces.

Compression Set

This is the ability of the O-ring to spring back to its original shape after it was compressed. A low compression set figure, typically less than 30% (approximately 50% is the industry average), translates into better long-term sealing performance. This is because the O-ring has retained its resilience and sealing force. A high compression set indicates the O ring will take a permanent set and not return to its original form causing leakages.

Abrasion Resistance

You want materials with high abrasion resistance to prevent wear and premature failure. While not typically quoted with a single numerical value, material data sheets often provide relative abrasion resistance ratings (e.g., excellent, good, fair) or a specific abrasion index based on standardized tests. For demanding dynamic seals, look for materials known for superior wear properties, such as high-durometer Nitrile or Polyurethane.

Permeation Resistance (for gas sealing)

This refers to sealing gas or how well the material prevents gas flow. You need low-permeation materials to minimize gas leakage over time.

Flexibility and Resilience

It’s a comparison of materials based on their relative resistance (e.g., butyl rubber has great permeation resistance while silicone has poor resistance).

Common O-ring Materials and Their Characteristics

| Material | Temperature Range (°F / °C) | Chemical Resistance & Features | Typical Applications | Limitations | Hardness Range (Shore A) |

| Nitrile (NBR / Buna-N) | -65 to +275°F (-54 to +135°C) | Excellent resistance to petroleum oils, hydraulic fluids, water, alcohols; poor resistance to ozone, sunlight, ketones, acids | Hydraulic systems, fuel and oil seals, general machinery | Low resistance to ozone, sunlight, ketones, strong acids; flexibility decreases with higher acrylonitrile content | 40–90 |

| Ethylene Propylene Diene Monomer (EPDM) | -65 to +300°F (-54 to +150°C) | Excellent resistance to water, steam, heat, weather, ozone, detergents; poor resistance to mineral oils and greases | Outdoor seals, steam systems, plumbing, HVAC, car radiators, water treatment | Not compatible with petroleum oils and greases | 40–90 |

| Fluoroelastomer (FKM / Viton™) | -15 to +400°F (-26 to +204°C), some grades -65 to +450°F (-54 to +232°C) | Outstanding resistance to high temperatures, oils, fuels, chemical corrosion; good ozone and weather resistance | Chemical processing, aerospace, automotive fuel and oil seals, high vacuum pumps | Poor resistance to ketones, some brake fluids, amines, hot water (some grades) | 50–95 |

| Silicone (VMQ / PVMQ) | -175 to +450°F (-115 to +232°C) | Excellent high/low temperature resistance, non-toxic, odorless, good aging and compression set; poor wear resistance | Food, medical, electronics, high-cleanliness environments, dry heat | Poor abrasion resistance; not compatible with ketones, acids, silicone oils, brake fluids | 40–80 |

| Polytetrafluoroethylene (PTFE / Teflon) | -320 to +450°F (-196 to +232°C) | Exceptional chemical resistance to almost all fluids and gases, excellent electrical insulation, very low friction | Severe chemical environments, aggressive fluids, chemical processing | Low elasticity and plasticity; not reusable after compression | N/A (rigid material) |

| Perfluoroelastomer (FFKM / Kalrez®, Chemraz®) | -15 to +600°F (-26 to +316°C) | Extreme chemical and temperature resistance, very low swelling, excellent purity | Critical chemical, pharmaceutical, food, electronics applications under extreme conditions | Fragile at low temperatures | 70–90 |

| Polyurethane (PU) | -40 to +180°F (-40 to +82°C) | High abrasion and tear resistance, excellent elasticity and plasticity | Heavy-duty mechanical seals, hydro-pneumatic breakers, excavators | Poor resistance to water, glycol, acids, alkaline solutions, and high temperatures | 80–95 |

| Neoprene (CR) | -40 to +250°F (-40 to +121°C) | Moderate resistance to oils, weather, ozone, refrigerants; good mechanical properties | Outdoor applications, refrigeration compressors, coolants, ammonia systems | Limited chemical resistance compared to other elastomers | 40–90 |

Types of O-Ring Seals and Applications

Many products use O-rings, such as push button switches and motors. And different products use different types of O-rings. Let’s look at what kinds of O-rings you can use and where you will need each one.

Static Seals

If the O-rings are of a static variety, they are applicable in situations where there is no relative movement between the materials being sealed and the O-ring. They can be used in applications such as sealing flanges, where two flat surfaces are held together with bolts. It also has widespread applications in face seals, two flat surfaces that meet and in grooves. An O-ring is compressed in a groove and a tight seal is made with a flat top mating surface to the groove.

Dynamic Seals

Dynamic O-ring seals allow relative motion of the sealed parts. In some reciprocating dynamic applications, O-rings may slide back and forth against the groove walls and on the downstream side of the groove, eventually causing the rubber to wear out. The O-ring remains rotating in hardened shafts, as found in pumps or motors.

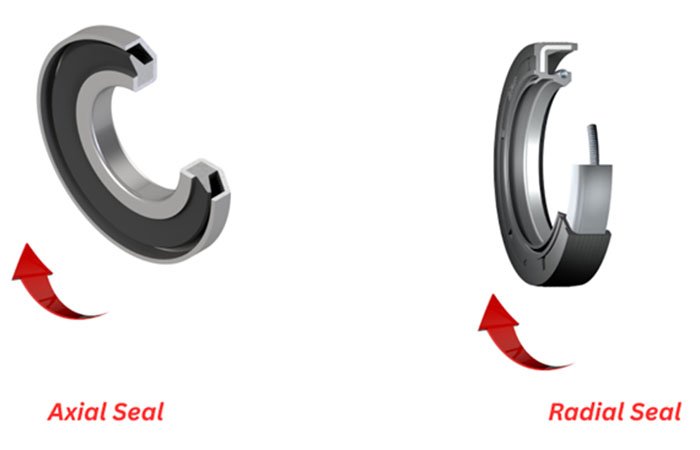

Axial vs. Radial Sealing

In axial sealing, the O-ring is compressed parallel to its axis, often seen in face seal applications where the sealing force is applied along the O-ring’s flat sides. For radial sealing, the O-ring is compressed perpendicular to its axis, typically when sealing around a shaft or within a bore, where the sealing force is applied to the outer or inner diameter of the O-ring.

O-ring Design Standards

Here are some things that you need to know when you are creating an O-ring. Let’s dive into each of them, beginning with the grooves.

Groove/Gland Design

The gland geometry is important since it directly influences how well your O-ring will seal. If the gland design is poor, overcompression, extrusion, or poor sealing may happen.

Types of Glands

- Face Seals: These static seals have a sealing surface without any gaps. They work well where there is little movement, and under pressure, the facing surfaces of the two parts do not get shifted.

- Static male/female glands: These have a gap between the mated components and are intended for static sealing applications. The gland has to be sized just right to manage compression and minimize extrusion.

- Dovetail Glands: These mechanically lock the O-ring in place, suitable for applications which require frequent disassembly. It also holds the O-ring in place in dynamic moving applications.

- Dynamic Seals: Seals for moving parts such as a piston or rods. Those, especially at relatively high inlet pressures, as under highway operating conditions, are required to reduce friction and wear. They also create a consistent seal against and around the plug all the time during varied pressure ranges and motion.

- Triangular Crush Groove Design: This is a different approach with a distinctive contact geometry that can offer some considerable advantages in the cases where the rectangular glands are not practical, or where low-profile grooves are required.

Critical Design Parameters

Compression (Squeeze)

With static seals, less squeeze is needed to ensure a tight seal. For dynamic applications, reduce that value to 10–20% to minimize friction and wear. Over-compressing should also be prevented as it can result in early failure from material fatigue and/or extrusion.

Stretch (Elongation)

Desirably, the stretch is in the range of 0 to 5 %, 6 % being a maximum value in the majority of cases. However, it can go up to 15% for special applications. A firm stretch makes for a secure fit without stretching the O-ring out of shape. Overstretching reduces the cross-section and diminishes squeeze, thus reducing material overload.

Gland Fill

The O-ring takes up approximately 75% of the volume of the gland, with 25% remaining as void. This accommodates material swell, temperature expansion and width increase due to compression. Overfilling can cause extrusion or distortion under pressure.

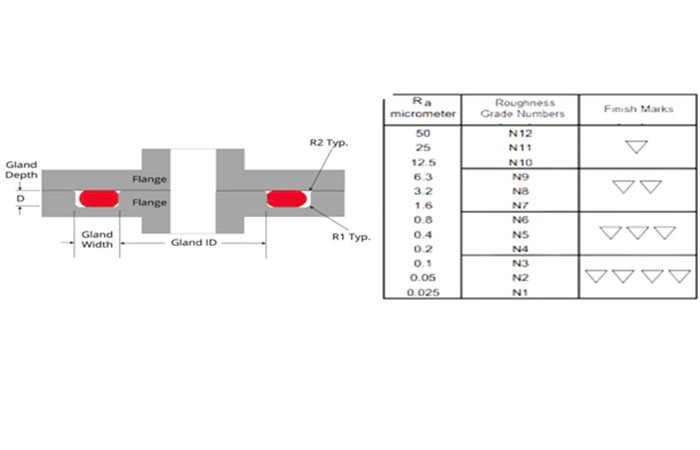

Surface Finish of Gland/Mating Surfaces

For static sealant and liquid, a roughness of surface of 32Ra would be acceptable. For gases, increase to 16Ra. 8-16Ra is preferred for dynamic applications where wear is a consideration. Rough surfaces can cause abrasion or spiraling, while overly smooth surfaces can retain inadequate lubrication, both of which degrade seal performance.

Sharp Corners

Be sure to chamfer all edges at 15°-20° to lead the O-ring when installing. Deburr all the corners to avoid cutting or nicking the O-ring and causing leakage or catastrophic failure.

Pressure

When creating with pressure, use a sufficiently hard O-ring to meet the system parameters. Harder O-rings (such as 90 Shore A) will work for higher-pressure applications (generally above 5 MPa or 725 psi). Design an O-ring gland to reduce the extrusion gap between components to prevent the O-ring from being pushed out of the gland and pinched, which may result in failure (particularly extrusion in high-pressure spikes).

For high pressures or when wider clearance gaps cannot be avoided, backup rings made of PTFE or harder elastomers must be placed behind the O-ring to prevent extrusion. For pressure cycling systems, use high abrasion resistant O-rings or higher durometer ratings to ensure performance over time and not succumb to surface fatigue.

Temperature Considerations

O-ring materials respond differently to temperature extremes. For example, silicone operates from approximately –60°C to +230°C, while FKM (Viton) withstands –20°C to +200°C. Beyond these ranges, materials may harden, shrink, or crack. Thermal expansion of O-ring materials (approx. (1–4) × 10⁻⁴ /°C) and glands (e.g., aluminum ~23 × 10⁻⁶ /°C) must be accounted for to avoid dimensional mismatches. The uneven thermal expansion between the O-ring and its gland can cause gaps or over-compression, leading to leakage or failure.

Standards and Tolerances

Precise sizing and tolerance matching are vital to achieve an effective seal and extend O-ring service life. Common sizing standards include AS568 (USA inch sizes), JIS (Japanese Industrial Standard), BS (British Standard), and metric ISO sizes, each defining exact inner diameter and cross-section combinations. Tolerances affect how well the O-ring fits the groove; if it is too loose, leakage may occur. Too tight, and you risk excessive squeeze or damage. Always follow the recommended tolerance ranges from the standard being used to maintain sealing integrity.

Common O-Ring Problems and How to Troubleshoot Them

If you have chosen an O-ring and notice it’s not working properly, it might have one of these problems. Let’s look at how you can fix it.

Compression Set

Once your O-ring elasticity is gone and it is permanently flat, then it won’t recover and cannot seal properly. Rubber crushing is prone to defects such as prolonged exposure to high temperatures, excessive compression, aging, and materials with high compression sets. To address this, you need to replace the O-ring with one made of low-compression-set material (like FKM), optimize the configuration of the gland to avoid over-compression and restrict damage from heat and chemicals that contribute to premature failure.

Extrusion and Nibbling

Torn or chewed-up material on the low-pressure side of an O-ring is an indication of extrusion and nibbling. It happens due to excessive system pressure, clearance gaps that are too large, an elastomer that is too soft, or no backup support. If this is the case, you may need to lower system pressure wherever you can, tighten gland clearances, add anti-extrusion backup rings, and increase the durometer on the elastomer to prevent it from losing shape.

Abrasion and Friction

A flat, worn O-ring surface in the direction of motion indicates abrasion and frictional wear. Much of this is from a lack of lube, poor sealing surfaces, or higher movement of high speeds. Take care of it by running a well-lubricated, wear-resistant material, such as polyurethane, getting the surface finish down to the right Ra, and removing the abrasive stuff from the system.

Installation Damage

Cuts, gouges, twists or pinches are typically signs of an O-ring that was improperly installed. This may happen as a result of sharp or rough edges, dry fit or not the correct size. To avoid it, deburr all edges, add a lead-in chamfer (15°–20°), lubricate the O-ring when installing it and confirm that you’re using the correct size to avoid overstretching or twisting.

Chemical Degradation

If the O-ring exhibits blisters, pitting, cracking, or hardening, it has become chemically deteriorated. This can happen if the elastomer interacts with chemicals it wasn’t designed to tolerate. Remedy this by choosing an O-ring from a proven chemically compatible O-ring material for your application (such as FFKM for aggressive chemicals) and minimizing exposure to non-compatible fluids.

Explosive Decompression

Blisters or tears on the surface of the O-ring following a rapid reduction in pressure mean that the O-ring has experienced explosive decompression. This phenomenon occurs because the trapped gas within the elastomer expands too quickly. Decompression-resistant materials, such as FKM compounds designed specifically for this purpose, can be used, and the system pressure can be released slowly enough to prevent a rapid expansion of the gas.

Outgassing/Extraction

A smaller cross-sectional size may not be visible but will indicate outgassing or pulling out, which may often be the result of under-cured elastomers or exposure to vacuum environments. You can correct by going with vacuum-compatible O-rings that are fully cured and harder, and avoiding plasticized compounds that can plasticize under vacuum.

Spiral Failure

If your O-ring shows a spiral wear pattern, it’s a result of uneven movement from eccentric components, wide clearance gaps, or inadequate lubrication. To fix it, align components more accurately, use harder O-rings or anti-spiral designs, narrow the clearance gap, and apply appropriate lubrication to reduce side loads and sticking during motion.

O-Rings Storage and Maintenance

- Store in a cool, dry place away from direct sunlight, high temperatures, and moisture to prevent degradation

- Utilize original packaging or airtight containers to mitigate oxidation.

- Check for aging or wear and replace based on usage frequency and operating conditions.

- Replace damaged or leaking O-rings immediately.

FAQs

- What are O-rings in an engine?

To prevent leaks of oil, coolant, fuel, or exhaust gases between various engine components like cylinder heads, manifolds, and fluid lines.

- Why do you need an O-ring in an injector?

The O-ring on an injector seals the injector body to the fuel rail and/or the intake manifold, preventing fuel or air leaks and ensuring proper fuel delivery into the engine.

- What is the difference between a gasket and an O-ring?

An O-ring is the kind of donut-shaped gasket that is within a channel. On the other hand, a gasket is a thin piece of material cut into the required shape and then compressed between two smooth surfaces where the seal is formed.

- What are O-rings used for?

O-rings are used to create a static or dynamic seal to stop fluid or gas from leaking in various applications like hydraulic systems, automotive engines, plumbing, medical equipment, and various components of the aerospace industry.

- How do you know what size O-ring you need?

You determine the O-ring size by measuring its Inside Diameter (ID) and Cross-Sectional (CS) diameter and then comparing these measurements to industry standards like AS568.