Let’s look at toggle switches, the different types, how to wire one up, and how to choose the right one for the application. You’ll also learn when to use them and where not to, how to diagnose common problems, and how to maintain them so they continue to do their job.

What Is a Toggle Switch?

A toggle switch is an electrical switch with a lever or handle that can be pushed one way to open a circuit or push the other to close a circuit. You’ll find toggle switches in everyday applications, from appliances to industrial control panels. They provide a sturdy, tactile way to turn things on and off or to change between different circuit paths.

How Does A Toggle Switch Work?

A toggle switch simply operates by changing the position of one of two (or more) contacts. When you flick a switch, you’re really connecting or disconnecting two metal contacts inside the switch that allow or prevent the flow of electricity in a circuit connected to the switch. You may open or close a single circuit depending on your toggle switch. Or, you may be opening and closing several circuits.

Types of Toggle Switches

There are several types of toggle switches, and knowing how to choose the right one is important for your project. Let’s look at the main types you will likely encounter.

SPST (Single Pole Single Throw)

The SPST toggle switch is the most basic and most widely used type you’ll find. It comes with only two terminals – one for powering the circuit and one for output. When you throw the switch, it does one of two things – completes or breaks the circuit, and your device is on or off. Due to its simplicity, SPST switches are perfect for something as simple as a basic on/off switch for a lamp or something much more complex like a field effect transistor (FET) or a motor.

SPDT (Single Pole Double Throw)

The SPDT toggle switch provides an extra bridge to switch 1 input between 2 outputs. It has three terminals: one common terminal connected to the input and two output terminals. When you toggle the switch, it makes contact between the input and one output or the other. This type is ideal if you select 1 of 2 devices or circuit paths with a single switch.

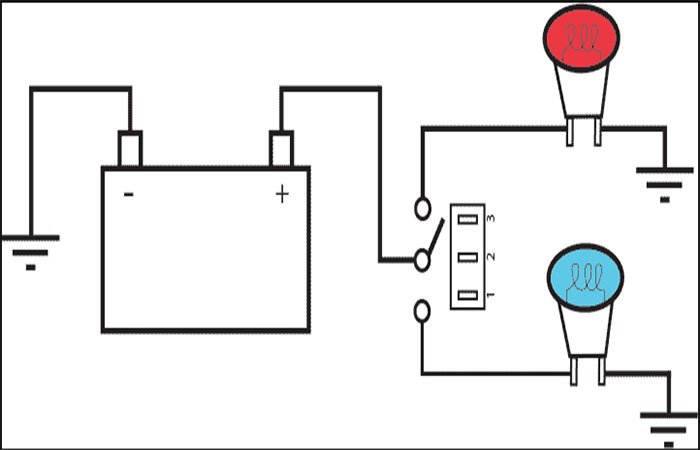

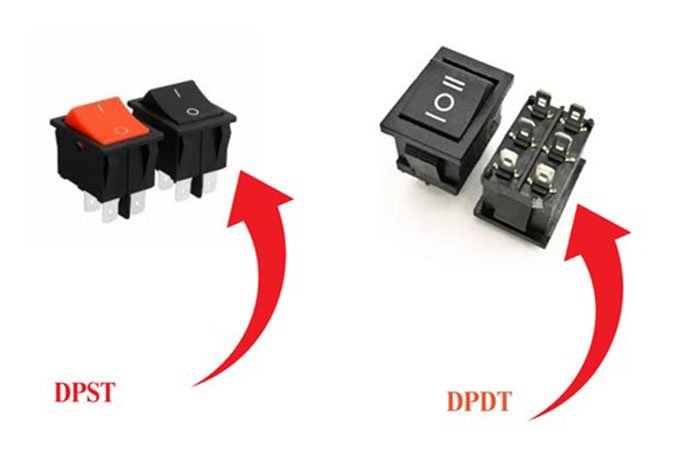

DPST and DPDT (Double Pole)

DPST switches control two independent circuits and act like identical, mechanically linked ones. The DPST switch works as if it were comprised of two separate SPST switches on the same switch with an actuator. The actuator controls either of the switches by moving in the actuation direction.

On the other hand, a DPDT switch is a combination of two SPDT switches, allowing you to switch two inputs into two outputs simultaneously. They are handy in more complicated arrangements, like reversing the direction of a motor action or controlling several devices from one switch.

How to Wire a Toggle Switch

Next, let’s look at how you need to wire your toggle switch.

Ensure the power supply is turned off before making any connection. Then, wire your toggle switches as follows:

How to Wire a 2-Pin Toggle Switch

A two-prong toggle switch is as easy to wire as it is to add to your existing system. One of the prongs connects to the power source, and the other connects to the device you want to control. Flipping a switch closes or opens that circuit, turning your device on or off.

How to Wire a 3-Pin Toggle Switch

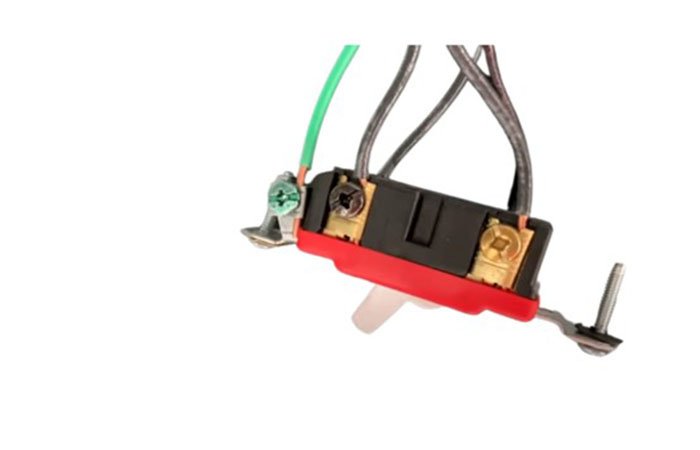

With a 3 terminal toggle switch, you have one extra terminal that offers more functionality. Usually, one prong is for power, a second is for the device connection, and a third is for an indicator or to switch between two outputs. Connect the power wire to an input terminal your device to the output terminal, and if you’re using an indicator or a secondary device, hook it up to the remaining terminal.

When and Where To Use A Toggle Switch

As simple, effective bearing maintainers, toggle switches have their place in all sorts of industries.

- Automotive: In cars and trucks, they control everything from headlights and fog lights to fans and custom electronics. They are designed to handle all of the vibrations and bumps the road will throw at them, so they are a favorite in car and truck modifications.

- Home: For home and DIY projects, you can use this toggle switch to control lamps, power tools, and hobby electronics. Their tactile response and simplicity make them perfect for custom control panels and special lighting effects.

- Marine and Industrial Purpose: The marine and industrial sectors also use toggle switches extensively. Their enduring performance in all weather conditions, particularly when used with a weatherproof cover or guard, matches that of more costly materials such as steel.

How To Choose The Right Toggle Switch

Choosing the perfect toggle switch for your task is not just picking up the first one you see on the shelf. Here’s what you need to look for.

Match The Voltage And Current Requirements

You’ll want to ensure that your circuit’s voltage and current are compatible with the switch’s ratings. Using a switch not rated for your application can cause the switch to overheat and fail, or worse, pose a fire hazard. It’s always best to check the manufacturer’s specs and err on caution if you’re unsure.

Look for Environmental Ratings (IP Rating)

Environmental ratings, like IP (Ingress Protection), are crucial if your switch will come into contact with dust, moisture, or other harsh substances. Go for toggle switches with an IP65 or greater rating for protection against water jets and dust.

Consider Panel Mount vs. PCB Mount

You’ll also need to choose between panel-mount and PCB (printed circuit board) mount switches. A panel-mount switch is for mounting on the panel or the wall. It’s good for on-off-on circuits and alternatives like step-easy, safe access with professional design. PCB-mount switches are soldered onto the circuit board, which is suitable for small or integrated electronic projects.

Troubleshooting Common Toggle Switch Problems

Sometimes, your toggle switch may have issues and fail to work as expected due to some errors. Here’s how to solve the most common problems with on/off switches.

Switch Not Working or Stuck

The most dependable slide switch can experience wear and tear over its lifetime. If your switch doesn’t work or seems stuck, it may have been caused by internal wear, debris, or corrosion. Try gently activating and sliding the switch back and forth to see if it loosens after being exercised. If not, replacement is probably the best course of action.

Flickering or Intermittent Power

If a light flickers or loses power intermittently, it likely means you have a connection that’s either becoming loose or already is loose somewhere in the switch or the wiring leading to it. Try to find out if the terminals are corroded and if all plugs are joined well. Sometimes, the issue is due to dirty contacts or poorly seated wires.

Overheating or Burning Smell

Disconnect the power from the switch immediately if you detect overheating or smell a burning odor. This indicates that the switch is either overloaded or has a fault. It can also be hazardous to continue using it in this condition. Replace the switch with the rightful voltage/current rate, and ensure your wiring is not damaged.

Maintenance Tips For Long-Term Use

Use these best practices to enhance the longevity of your switches.

Periodically Test With A Multimeter

Performing regular testing with a multimeter is a wise idea to ensure that your toggle switches keep working reliably in the long run. This will enable you to check if the switch is contacting properly and if there’s no resistance or disconnected circuits somewhere.

Keep the Switch Clean and Dry

Equally important is keeping the switch clean and dry. Dirt, water, and other contaminants can penetrate the mechanism, resulting in loss of output or malfunction. Regularly clean the switch and its vicinity, and consider a weatherproof cover if the switch is not weather-protected.

Check Connections Regularly

If you feel the switch is becoming hard to toggle, loose, or damaged, don’t wait too long before replacing it. A damaged or defective switch is inconvenient and can be a safety hazard. Changing out a switch is a simple and inexpensive way to keep your electrical systems reliable and safe.

FAQs

1.What is the difference between a 2-prong and a 3-prong toggle switch?

A 3-prong switch has a ground wire, which is added to industrial switches for safety against shock and fires, and it’s not included in a standard 2-prong switch.

2.Can you wire a toggle switch without a relay?

Yes, when dealing with low voltage and low current and when the switch directly controls the load. For more power, use a relay to save the switch.

3.Is it possible to dim a toggle switch?

No, a standard on-off toggle is an on-off switch. It either completes an electric circuit or entirely breaks it. To perform dimming, a different switch or a control device with the ability to control the current or voltage is necessary.